CAD HR MURAL PX

Old ranges

Counter flow - Forward - ECM < 1 200 m3/H

View larger

View larger

CAD HR MURAL PX

New product

| ErP 2018- UVNR compliant Variable EC motors |

Filters

|

|||

Air-to-air plate heat exchangers produced by the RECUTECH company, which participates in the Eurovent program. Certification for AAHE. |

- Economic range

- Low noise level

- Multiple connection configurations

Application

Air introduction and extraction with energy recovery.

Indoor or outdoor installation.

Horizontal or vertical installation depending on the model.

-

Description

-

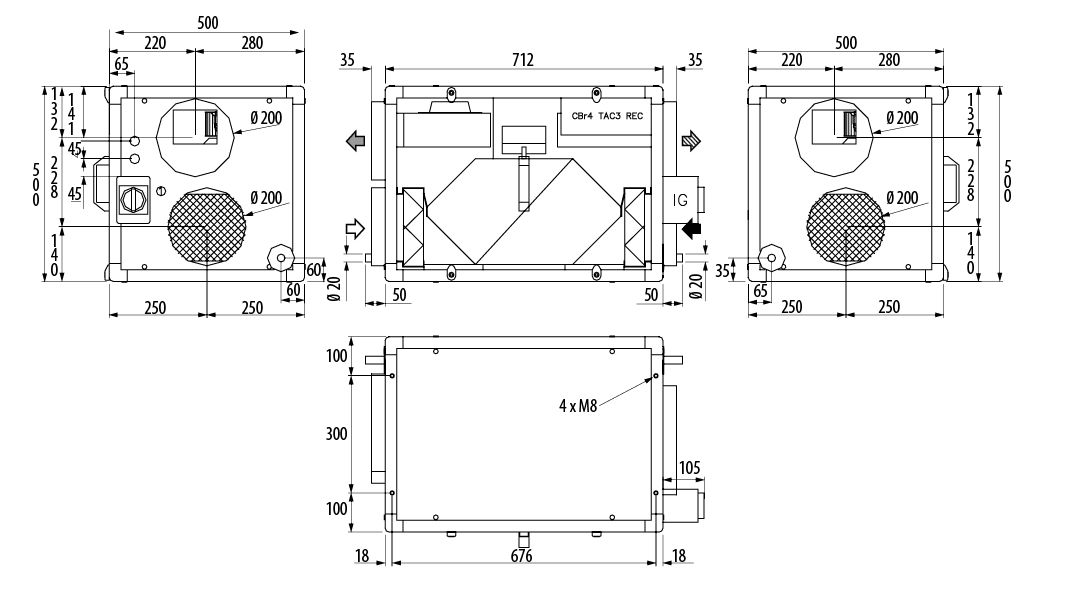

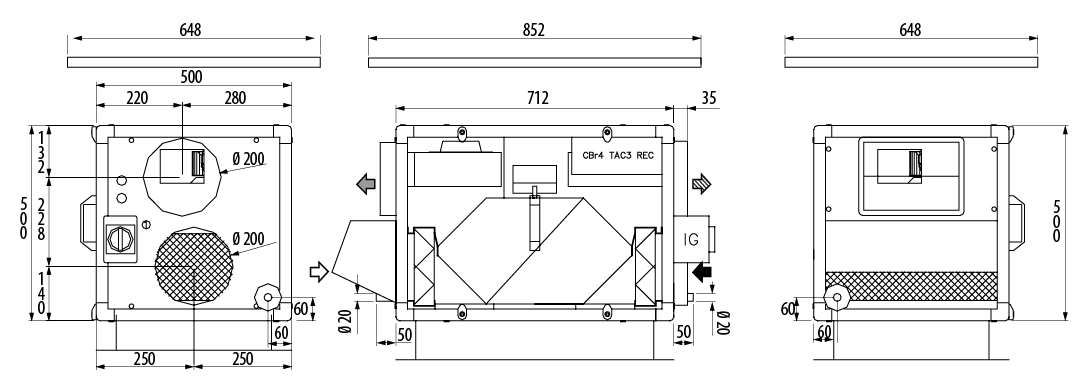

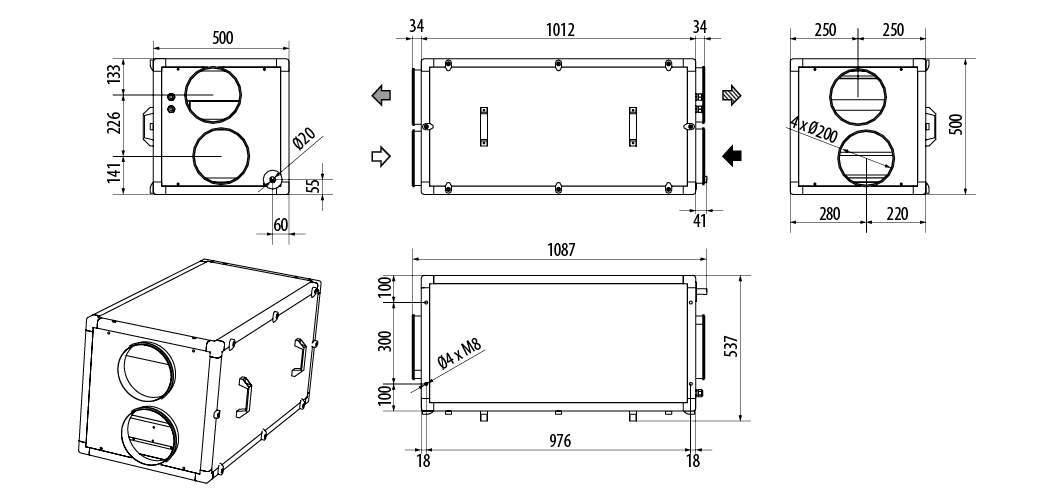

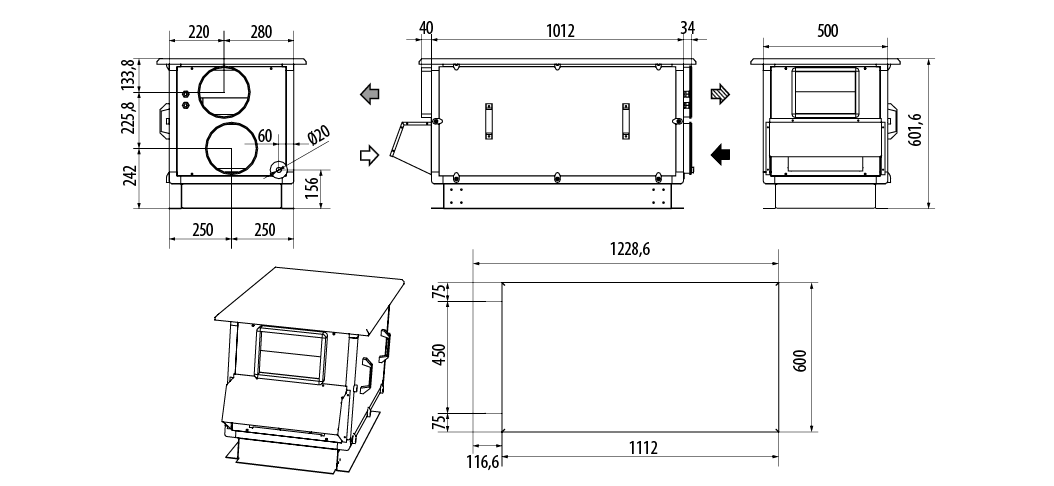

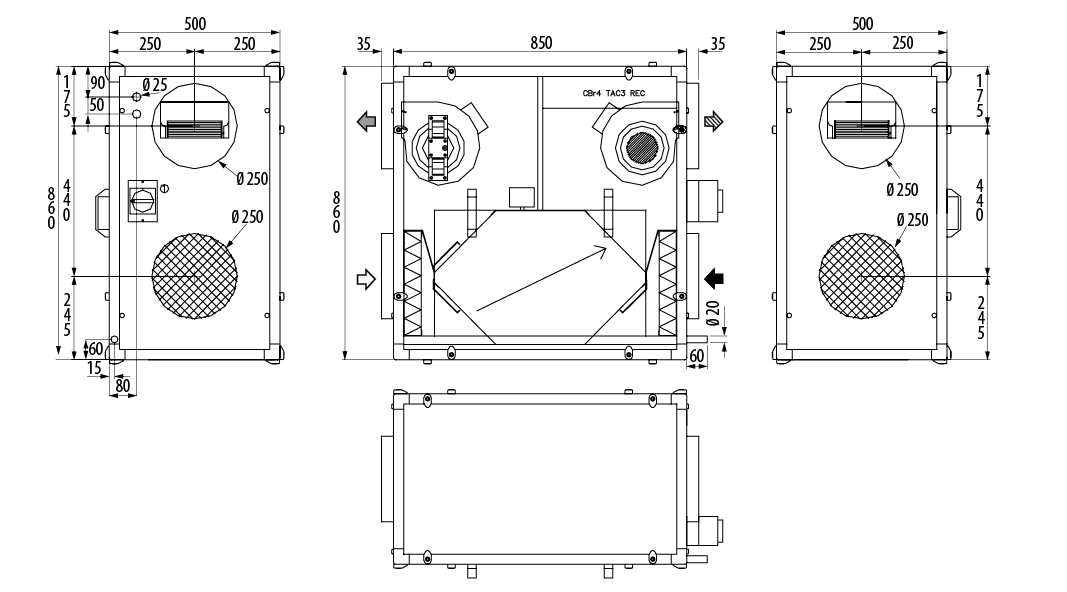

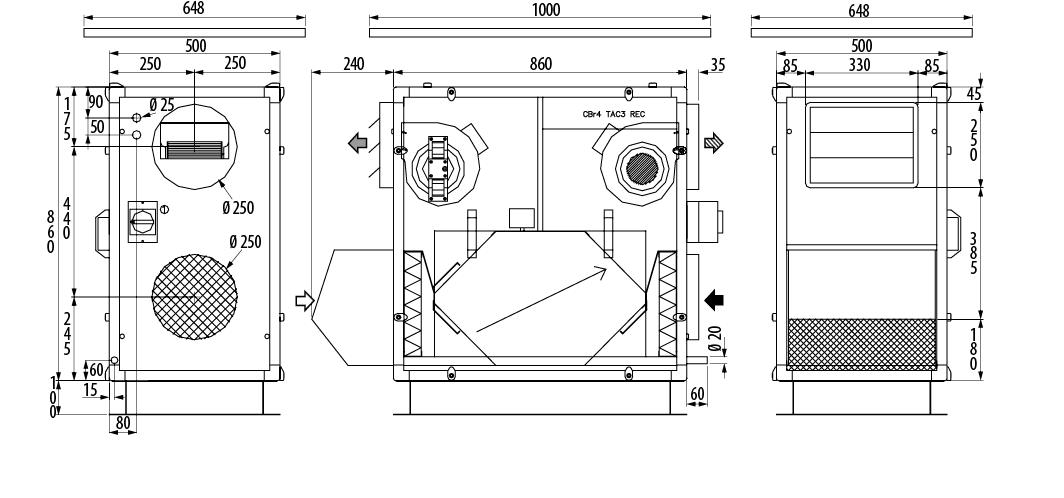

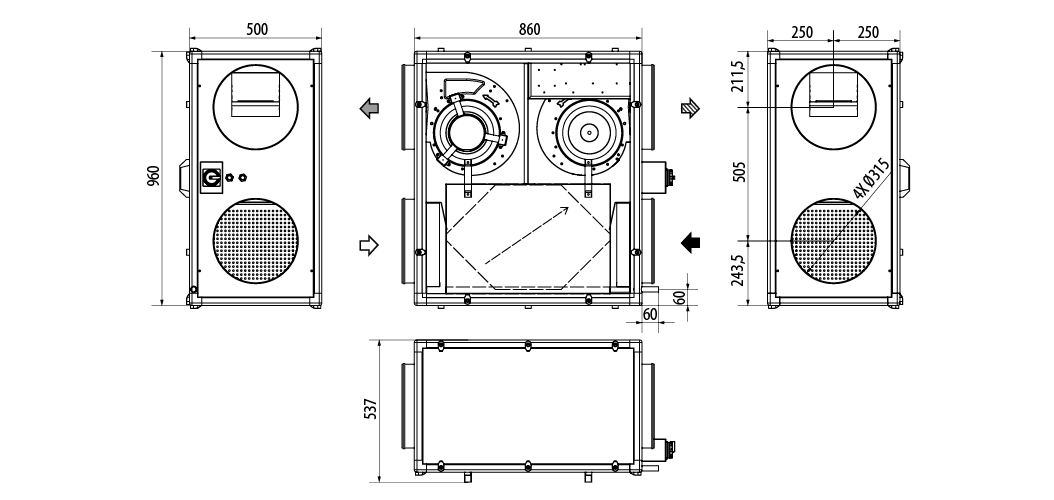

Dimensions

-

Documentation

-

Public Price

-

Software

-

References

2 models:

- R: blowing on the right of the control box,

- L: left blowing (on request).

Horizontal or vertical installation depending on the model.

Connection of ducts in line.

TAC5 DM regulation: integrated screen and programming keys.

Communicating TAC5 regulation:

- Modbus RTU- RS485,

- Modbus TCP / IP,

- KNX TP,

- Wifi: smartphone application, tablet,

- Ethernet: PC application,

- BACnet gateway.

Construction

- Box with structure in anodized extruded aluminum profile.

- Double skin panel 15 mm thick with rock wool insulation (Euroclass A1) thermal conductivity 0.035W / (mk):

- External finish in prepainted steel of silicone heat-crosslinkable polyester type (5 μm primary + 20 μm polyester).

- Interior finish in galvanized steel.

- Access to the filters and the exchanger from the main face using a removable panel.

- Condensate collection tray with Ø 20 mm drain.

- By-pass 50%.

- Supplied with 3 mounted / wired probes for automatic bypass management.

Motorization

- Centrifugal fans with action on CAD HR MURAL PX FW, with reaction on CAD HR MURAL PX 450 model.

- Low consumption, direct current, single phase 230V ECM motor. Electronic thermal protection - manual reset.

Exchanger

- High efficiency air / air countercurrent heat exchanger made of aluminum for an operating temperature of up to 80 ° C. Thermal efficiency up to 92%.

Filters

- G4 filters (Coarse 65%) the extraction and introduction of air. Easily accessible from the main side.

- For size 450:

- G4 filters (coarse 65%) the extraction and introduction of air.

- As an accessory, filter replacement kit with G4 filters (coarse 65%) at extraction and F7 (ePM1 60%) on the air inlet.

- For sizes 600 to 1200:

- M5 filters (ePM10 50%) the extraction and introduction of air.

- As an accessory, filter replacement kit with M5 filters (coarse 65%) at extraction and F7 (ePM1 60%) on the air inlet.

TAC5 DM control unit ready to connect

- Complete regulation allowing 3 operating modes:

| SETTING THE FLOW RATES | RECOMMENDED APPLICATIONS |

| LS MODE - VARIABLE FLOW RATE | |

| Fan speed variation by 0-10 V signal | |

| - Flow rate setpoint value based on a 0-10 V signal from an external sensor (CO2, temperature, humidity, etc.). | - Single-zone installations, requiring adaptation of ventilation according to occupancy |

| AC MODE - CONSTANT FLOW | |

| Fan speeds defined according to a precise flow rate | |

| 3 maximum constant flow setpoints, input of values with reading on display. Switching between the different setpoints carried out manually from the remote control or automatically by clock (not supplied) or presence detection. |

Installations requiring the control of one or more precise flow rates. |

| CPs MODE - CONSTANT PRESSURE | |

| Automatic variation of fan speed to maintain constant pressure | |

| Flow automatically modulated in order to maintain a constant pressure value measured by an external probe (pressure probe as an accessory). | Multi-zone ventilation systems, associated with modulation of terminal airflows. |

- The operation of the exhaust fan is slaved to the supply fan. Its flow rate corresponds to a percentage of the flow rate of the supply fan (generally 100%).

Regulation accessories

- HMI TACtouch 4.3 ”touchscreen, IP20, for parameter setting, control, visualization.

- SAT3:

- Signals the actual operation of the fan (relay R3) via a potential-free contact (relay normally open).

- Ex: authorization of operation of an external battery (post-ventilation function that can be programmed).

- Signals the alarm on a pressure variation (relay R2).

- SAT TAC5 BA / KW:

- Modulates the power of the batteries in order to maintain the supply temperature equal to the setpoint.

- Provides antifreeze protection for water coils.

- Gives a control contact for the circulator.

- Manages the hot / cold passage via a digital input.

Allows the batteries to be switched off via a digital input.

- SAT MODBUS, allows the options below:

- Connection to a GRC (remote control with touch screen),

- Modbus RTU communication

- Control and visualization via a BMS.

- SAT ETHERNET:

- Communication with Modbus TCP / IP protocol in Ethernet network

- On 10 BASE T twisted pair. Allows communication with a BMS or interfacing with the EOLE4HR application for smartphone, tablet and PC (Android, IOS or Windows 7/8/10).

- SAT WIFI:

- Communication with Modbus TCP / IP protocol by WIFI. Allows communication with a BMS or interfacing with the EOLE4HR application for smartphone, tablet and PC (Android, IOS or Windows 7/8/10).

- CA kit for CAD HR MURAL PX 450 (jet engine): includes one pressure sensor per fan. Allows by measuring the pressure, displaying and setting the flow rates in m3/ h.

Air treatment selection

| Outdoor air | |

| Extract air | |

| Supply air | |

| Exhaust air |

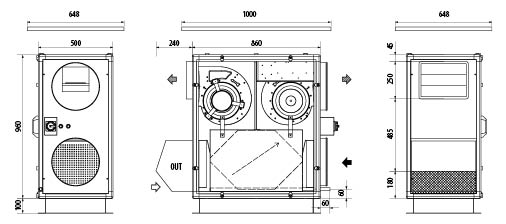

CAD HR MURAL PX FW 450 R

Indoor version - Vertical installation

CAD HR MURAL PX FW 450 R OUT

Outdoor version - Vertical installation

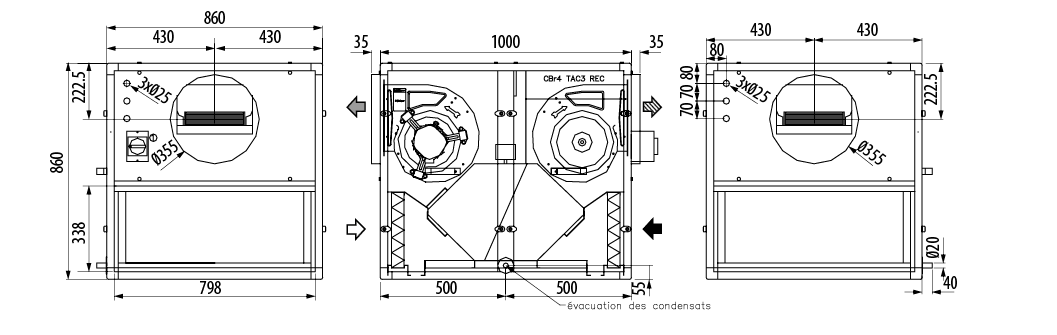

CAD HR MURAL PX 450 R

Indoor version - Vertical installation

CAD HR MURAL PX 450 R OUT

Outdoor version - Vertical installation

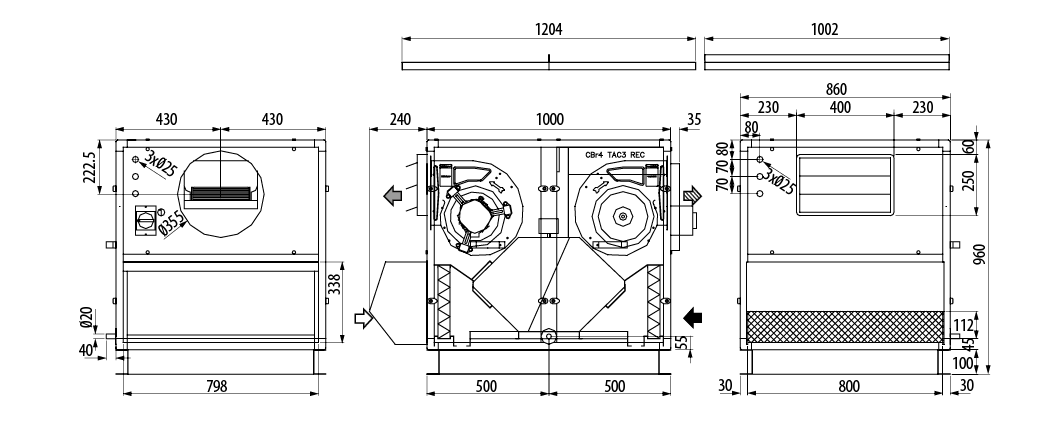

CAD HR MURAL PX FW 600 R

Indoor version - Horizontal or vertical installation

CAD HR MURAL PX FW 600 R OUT

Outdoor version - Vertical installation

CAD HR MURAL PX FW 800 R

Indoor version - Horizontal or vertical installation

CAD HR MURAL PX FW 800 R OUT

Outdoor version - Vertical installation

CAD HR MURAL PX FW 1200 R

Indoor version - Vertical installation

CAD HR MURAL PX FW 1200 R OUT

Outdoor version - Vertical installation

Detailed specifications

Detailed specifications

Text catalog pages (CT)

Installation instructions

Installation instructions

Installation instructions (NT)

Installation instructions (NT) Other