ErP - Ecodesign and energy labeling

GENERAL

With the objectives of reducing electricity consumption and more generally the impact on the environment of energy-consuming products (ERP: Energy Related Products), the European Parliament has established a framework and set requirements in terms of design and labeling of these products.

In our field of activity, 3 directives and 4 regulations apply:

- Regulation n ° 640/2009 - Directive 2005/32 / CE: Ecodesign requirements for electric motors - Valid until 06/30/2021

- Regulation n ° 1781/2019 - Directive 2005/32 / CE: Ecodesign requirements for electric motors - Valid from 07/01/2021

- Regulation n ° 327/2011 - Directive 2009/125 / CE: Ecodesign requirements for fans driven by a motor

- Regulation n ° 1253/2014 - Directive 2009/125 / CE: Ecodesign requirements for ventilation units

- Regulation n ° 1254/2014 - Directive 2010/30 / EU: Energy labeling of Residential Ventilation Units

These regulations concern manufacturers, importers or marketers such as VIM but also project managers (installation design offices) who know the environment and the conditions for integrating the product with its accessories into the installation. .

You will find below a summary of the main points concerning us, it does not exclude a complete reading of the official texts on your part.

You will find precise information for each VIM product range on the internet general presentation page and on the first page of the printed or pdf text catalog. Regulatory information sheets (FERP) are classified in the documents to download section.

In our quotes, after each item concerned, we also indicate the type of motor used and whether it is necessary to provide a variable speed drive.

REGULATION No 640/2009 until 6/30/21: MOT ORS ELECTRICAL

| Official text |Application fields

The motors concerned and the efficiency classes are based on standard IEC 60034-30.

- Induction motor, three-phase cage, single speed

- Nominal voltage Un

- Nominal power: from 0.75 to 375 kW.

- 2, 4 or 6 poles.

- Continuous operation (duty factor S1).

- Frequency 50 or 60Hz.

In the VIM ranges, the asynchronous motors B3 and B5 used on turrets, boxes, fans for comfort or smoke extraction applications and meeting these criteria are concerned.

Products not affected

- Single-phase motors.

- Electronically commutated ECM motors.

- Three-phase motors 1 speed 8 or 12 poles.

- Three-phase two-speed motors (independent windings or Dahlander winding).

- Motors fully integrated into another product making it impossible to measure motor fuel efficiency separately.

- Motors with a non-S1 service factor (discontinuous operation).

- Engines specifically designed to operate:

- in explosive atmospheres (ATEX motors) as defined in directive 94/9 / CE.

- at a maximum operating temperature above 400 ° C.

- at altitudes above 1000 m.

- at ambient temperatures above + 40 ° C or below -15 ° C (0 ° C if air cooled).

Performance requirements

- IE1: standard level output.

- IE2: high level performance.

- IE3: premium level performance.

- IE4: super premium level performance.

Mandatory deadlines

These application dates relate to the placing on the European market (or import) by manufacturers (or importer) of engines.

Since June 16, 2011, motors with a nominal power between 0.75kW and 375kW must have a

efficiency greater than or equal to efficiency level IE2.

Since January 1, 2015, motors with a nominal power between 7.5 and 375 kW must:

either have an efficiency greater than or equal to the efficiency level IE3,

or reach the IE2 efficiency level and be equipped with a variable speed drive.

From 1 January 2017, motors with a nominal power between 0.75 and 375 kW must:

either have an efficiency greater than or equal to the efficiency level IE3,

or reach the IE2 efficiency level and be equipped with a variable speed drive.

REGULATION No 1781/2019 from 01.07.21: MOT ORS ELECTRICAL

| Official text |Application fields

The motors concerned and the efficiency classes are based on standard IEC 60034-30.

- Single speed cage induction motor.

- Three phase.

- Single phase from July 1, 2023.

- Nominal power from 0.12 to 375 kW.

- 2, 4, 6 or 8 poles.

- Increased safety ATEX motors (fitted to devices other than those of group I according to directive 2014/34 / EU) from July 1, 2023.

- Continuous operation (duty factor S1)

- Frequency 50 or 60 Hz.

- Regulation No. 1781/2019 is applicable to variable speed drives from July 1, 2021.

In the VIM ranges, the asynchronous motors B3 and B5 used on turrets, boxes, fans for comfort or smoke extraction applications and meeting these criteria are concerned.

Products not concerned (non-exhaustive list)

- 12-pole motors.

- Three-phase two-speed motors (independent windings or Dahlander winding).

- Motors fully integrated into another product making it impossible to measure motor fuel efficiency separately.

- Motors with a non-S1 service factor (discontinuous operation).

- Engines specifically designed to operate:

in explosive atmospheres (ATEX motors) equipping group I devices as defined in appendix I of directive 2014/34 / EU. (Mines)- at a maximum operating temperature above 400 ° C.

- at altitudes above 4000 m.

- at ambient temperatures above + 60 ° C or below -30 ° C (0 ° C if air cooled).

Performance requirements

- IE1: standard level output.

- IE2: high level performance.

- IE3: premium level performance.

- IE4: super premium level performance.

REGULATION N ° 327/2011: FANS

| Official text |Application fields

Fans driven by an electric motor whose power is between 125 W and 500 kW.

In the ranges marketed by VIM are concerned fans, motor-fans, axial tubular fans and wall fans sold alone or integrated in a Ventilation Unit.

Exempt products

Products fitted with a single electric motor with a power less than or equal to 3 kW in which the fan is fixed on the same shaft as that providing the main function

Range hoods with maximum total electrical input power attributable to the fan (s) Fans designed specifically for operation in potentially explosive atmospheres.

Fans designed only for emergencies, in temporary service, having regard to the fire safety requirements set out in Directive 89/106 / EC

Fans designed specifically to operate:

- when the operating temperatures of the displaced gas exceed 100 ° C

- when the operating ambient temperature for the motor, if it is outside the gas flow, which drives the fan exceeds 65 ° C

- when the average annual temperature of the displaced gas and / or the ambient operating temperature for the engine, if it is outside the gas flow, are below - 40 ° C

- with a supply voltage> 1000 V (AC) or> 1500 V (DC)

- in toxic, highly corrosive or flammable environments or in environments containing abrasive substances

Mandatory deadlines

In application since 2013, with modification of the requirements since January 1, 2015.

Expiration 2020.

Information requirements

| ErP Explanatory Fan |

REGULATION N ° 1253/2014: VENTILATION UNITS

| Official text |Application fields

UV ventilation unit (UV): "electrical device equipped with at least one turbine, a motor and a box intended to replace the stale air with outside air in a building or part of a building"

This definition corresponds at VIM to ventilation boxes (extraction / insufflation), turrets and single or double flow air handling units.

Distinction between residential (UVR) and non-residential (UVNR)

- UVR = maximum flow does not exceed 250 m3 / h or whose maximum flow is between 250 and 1000 m3 / h but whose application is declared by the manufacturer as exclusively residential.

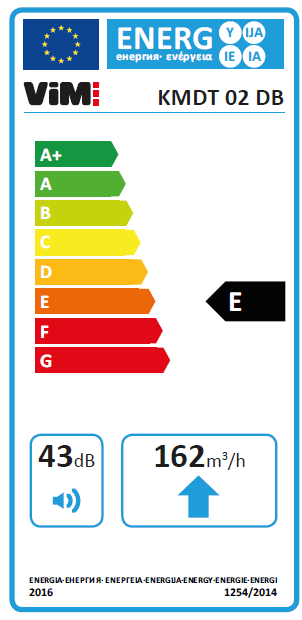

UVRs are also subject to the requirements of regulation n ° 1254/2014 which imposes, among other things, labeling on the product of energy performance (A + to G).

- UVNR = other products. Not subject to the tax on energy labeling.

Products "explicitly" exempted by the regulation (article 1)

- UVs for which the electric power absorbed is less than 30 W for single streams or 2 x 30 W for double streams. On the other hand, the information requirement remains.

- UV designed exclusively to operate in a potentially explosive atmosphere

- The VIM ATEX ranges are clearly identified on our catalog pages and on the internet.

- UVs designed exclusively to operate in an emergency, for short periods of time and which meet the requirements for construction works in terms of fire safety

- The F200 120 or F400 120 CE approved VIM ranges for smoke extraction only operation.

- UVs designed exclusively to operate with an ambient temperature, with the motor outside the air flow above 65 ° C.

- UV designed exclusively to operate with an ambient temperature or the temperature of the displaced air, engine out of the air flow, below -40 ° C

- Hoods

Products for process ventilation

The technical assistance office of the European Commission confirms that the regulation only applies to buildings or parts of buildings designed to house people and where the ventilation units are intended to replace the air stale by this human presence from outside air. The regulation does not apply for so-called "process" ventilation such as data centers, agricultural buildings, extraction above machines (compressors, foundries, forges, industrial furnaces, etc.)

The use of non-ErP compliant products is authorized and there is no obligation in terms of speed variation.

Products for professional kitchens

EVIA / Eurovent in its latest | guide of 03/10/2017 | (Q10. EI 139) deals specifically with this application.

- The UVU SUP (single flow CTA) intended for the introduction of fresh air are within the scope. Products must be ErP compliant.

- The UVU ETA (Extraction units) developed specifically for professional kitchens are not in the scope. Products that do not comply with ErP can therefore be used, no obligation in terms of speed variation.

Regarding the VIM range, this is the case for KUBAIR Kitchen option, KUBAIR ECOWATT Kitchen option, KCTR, KDTR Kitchen option, KABB, KABT - The UVU ETA (Extraction unit) not specially developed for professional kitchens are within the scope. Products must be ErP compliant. The rules regarding speed variation apply.

Energy performance requirements

Electrical efficiency of the complete unit, internal SFP of the machine, with or without filtration, efficiency of the exchanger, etc., the requirements depend on the type of unit.

For example, the minimum thermal efficiency requirement of exchangers is 67% on January 1, 2016 and 73% as of January 1, 2018.

Determining the actual performance of each unit involves laboratory measurements and calculation.

Requirements in terms of resources

- UVDF (double flow) must be equipped with a heat recovery system (SRC) and a bypass device. (BYPASS). Stopping the wheel (rotary heat exchanger) is considered a bypass.

- UVs equipped with a filter will be fitted with a visual warning signal for filter change (from 01/01/2018). A depressostat meets the requirement.

- All UVs, with the exception of dual-use units (ventilation and smoke extraction) will be fitted with a multi-speed motor or a speed variator.

Consequences for all UVs:

- UVs equipped with EC motors (ECM) comply as is

- UV units fitted with 3-speed + stop motors comply with the condition

- UV units fitted with single or three-phase AC motors must be associated with a voltage variator or a frequency variator. VIM will systematically offer the suitable drive.

Information requirements

| UVR Explanatory ErP | UVNR Explanatory ErP |

The regulations require us to provide you with 19 pieces of information for each UVR and UVNR category (appendix IV and V).

This information is available in the form of files (FERP) on our website www.vim.fr under each product range. (Section: documents to download)

Deadlines and countries concerned

The first deadline is at 01/01/2016 and the second with new requirements in terms of performance at the 01/01/2018.

From a regulatory point of view, on this date, VIM , as the marketer, is required to deliver ErP compliant (UV) products, whether for new or replacement of installed products.

The countries concerned: EU countries + some overseas countries and territories + states EFTA / EEA + Turkey

The Azores, Germany, Austria, Belgium, Bulgaria, the Canaries, Cyprus, Croatia, Denmark, Spain, Estonia, Finland, France, Greece, Guadeloupe, Guyana , Hungary, Ireland, Iceland, Italy, Liechtenstein, Lithuania, Latvia, Luxembourg, Madeira, Martinique, Malta, Norway, the Netherlands, Poland, Portugal, Czech Republic, Reunion, Romania, United Kingdom, Saint-Barthélemy, Saint-Martin, Slovakia, Slovenia, Sweden, Monaco, Andorra, San Marino, Turkey, Switzerland.

It is possible to market UV VIM not ErP compliant in countries not concerned, provided that they comply with local regulations and that the product is still available.

REGULATION N °1254/2014 : ENERGY LABELING OF RESIDENTIAL VENTILATION UNITS

| Official text |For Residential Ventilation Units, this regulation reinforces the information obligation through an energy label which must be found in the packaging and on the website.