- VIM

- Our engagements

- Our means

- Join us

- FERRARI France

CSR

A long-term, proactive, comprehensive and pragmatic approach

Our ventilation products and systems are an essential building block in the construction and renovation of buildings to make them less energy-consuming, more sustainable, and healthier. Depending on their purpose, they contribute to improving indoor air quality, reducing exhaust air pollution, improving acoustic and thermal comfort, preserving the building, or ensuring personal safety in the event of a fire.

As a major player in the design, manufacture and distribution of finishing products for building professionals, VIM 's management and staff have been committed for many years to greater social, environmental and societal responsibility.

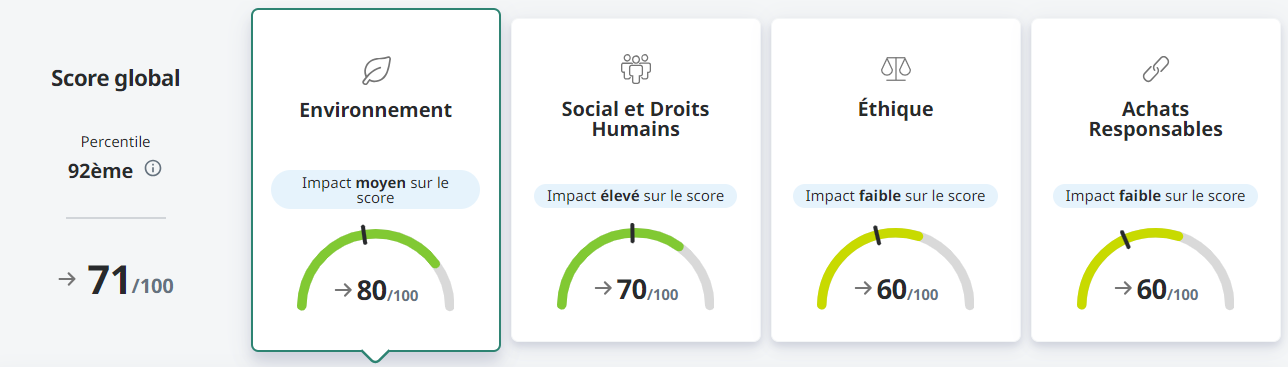

An approach evaluated by ECOVADIS

|

VIM was assessed in 2024 at “SILVER” level by the ECOVADIS rating platform | http://ecovadis.com/fr/ | |

|

|

Carbon footprint 2023 - VIM Ventilation experts

Download the BEGES VIM 2023 in pdf

Methodology:

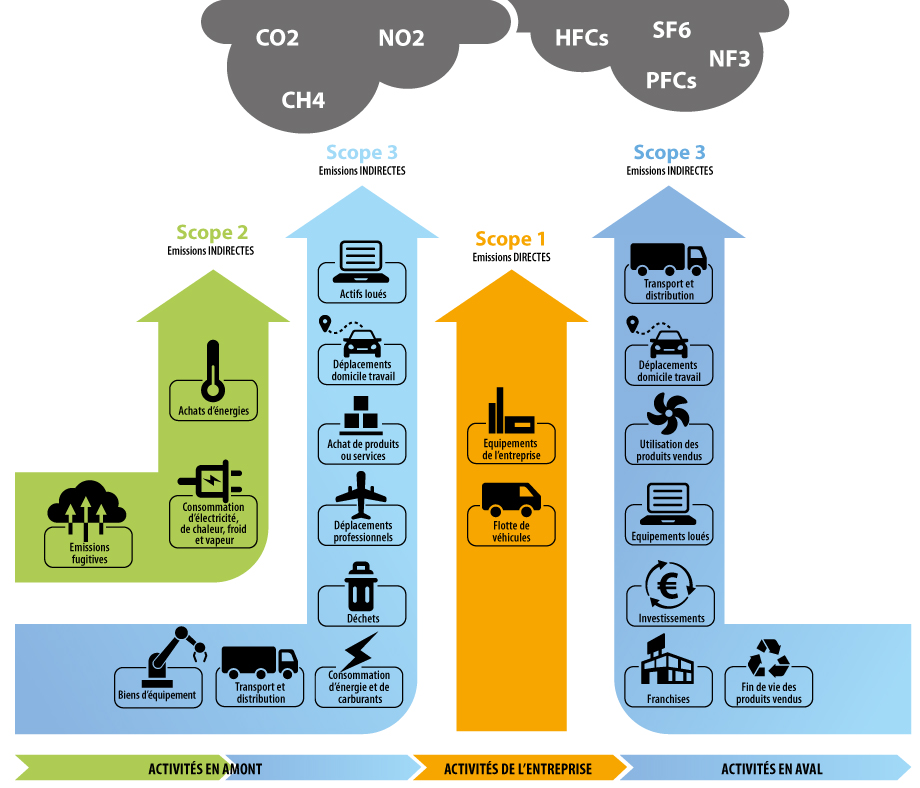

- The Greenhouse Gas Emissions Assessment (BEGES) of the company VIM (Legal Person) was carried out using the NuaGES tool designed by the Ministry of Ecology on behalf of state services and consolidated by APESA on behalf of the DREAL Nouvelle Aquitaine, whose support we received.

- The data is published on the official ADEME website: Identity sheet - Consultation publication form - GHG balances

|

|

2023 Declaration Table

|

|||

| Emission categories |

Positions |

Job descriptions | Total tCO2eq | Relative weight |

| CAT 1 (SCOPE 1) Direct GHG emissions |

1.1 | Direct emissions from stationary combustion sources | 8.5 | 0.01% |

| 1.2 | Direct emissions from mobile sources with thermal engines | 136.5 | 0.18% | |

| 1.3 | Direct fugitive emissions | 35.6 | 0.05% | |

| Subtotal | 180.6 | 0.24% | ||

|

CAT 2 (SCOPE 2) |

2.1 | Indirect emissions linked to electricity consumption | 78.8 | 0.10% |

| Subtotal | 78.8 | 0.10% | ||

|

CAT 3 (SCOPE 3) |

3.1 | Upstream freight transport | 291.9 | 0.38% |

| 3.2 | Downstream freight transport | 465.9 | 0.61% | |

| 3.3 | Home-work travel | 346.0 | 0.45% | |

| 3.5 | Business trips | 7.2 | 0.01% | |

| Subtotal | 1 110.9 |

1.46% | ||

|

CAT 4 (SCOPE 3) |

4.1 | Purchase of goods | 26 192.2 | 34.42% |

| 4.2 | Immobilization of assets | 761.4 | 1.00% | |

| 4.3 | Waste | 22.0 | 0.03% | |

| 4.5 | Purchase of services | 329.7 | 0.43% | |

| Subtotal | 27 305.3 | 35.88% | ||

|

CAT 5 (SCOPE 3) |

5.1 | Use of products sold | 44 173.5 | 58.05% |

| 5.3 | End of life of products sold | 3,250.5 | 4.27% | |

| Subtotal | 47,424.0 | 62.32% | ||

| TOTAL |

76,099.6

|

100.00%

|

||

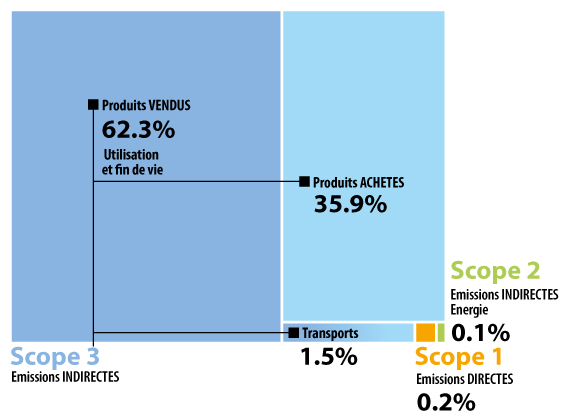

Declaration Table - Analysis

- SCOPE 1 and SCOPE 2

Direct GHG emissions and indirect emissions linked to electricity consumption represent only 0.34% of total emissions.

Overall, we are talking about around 259 tonnes of CO2 equivalent (tCO2eq) for the year 2023.

- SCOPE 3

Category 3 - Indirect emissions from transport

These emissions represent 1.46% of total emissions.

The goods come from 96% from Europe, they are transported by trucks to supply our stock and our factory in Deux-Sèvres (79).

Downstream transport (466 tCO2eq) corresponds to delivery by truck to our customers, directly to construction sites or to their sites.

Commuting to and from work is primarily by motorized vehicle (individual or carpooling). The main site is not served by public transport.

Category 4 - Indirect emissions associated with purchased products and services

These emissions represent 35.9% of total emissions. This is a significant portion of GHG emissions.

These are mostly emissions linked to the purchase of goods (4.1), raw materials (steel, stainless steel, wood, cardboard, aluminum, packaging plastics, etc.), components (motors, batteries, exchangers, electrical components, insulators, fans, etc.), supplies and finished products.

The waste collection and treatment share represents only 22 tCO2eq.

Category 5 - Indirect emissions associated with products sold

This is the largest share of emissions representing 62.3% of the total. Some of our products consume electricity to operate. In the case of VMC, for example, operation is continuous.

Transition Plan - Main actions

- SCOPE 1 and SCOPE 2

Although low compared to SCOPE 3 emissions, they are subject to a reduction plan aimed at reducing electricity consumption:

Complete relamping of the production and logistics areas of the old building - completed at the end of 2024

Installation of photovoltaic panels with a power of 500 kWc - Self-consumption at 100%, to be put into operation in 2025

Replacement of the company's diesel vehicles with hybrid and electric vehicles.

The goal is to reduce direct and indirect emissions by 16% by 2025.

- SCOPE 3

Category 3 - Indirect emissions from transport

The reduction in emissions from freight transport is directly linked to the strategies of our carriers, who are also seeking to reduce their consumption of fossil fuels.

These strategies include renewing the fleet with cleaner vehicles (Euro 6, bioNGV, biodiesel, hybrid, etc.), optimizing driving logistics (eco-driving, route optimization, optimization of the fill rate, etc.).

For the home-work journey, emissions reduction will come from vehicle developments. The increasing use of hybrid and all-electric vehicles is contributing to this reduction.

From January 2025, VIM will provide head office employees with charging stations for electric vehicles.

Category 4 - Indirect emissions associated with purchased products and services

These emissions are directly proportional to the quantities purchased.

Reducing them involves, for example, the use of recyclable materials. This is already the case for galvanized steel, stainless steel, copper, and aluminum, which constitute a significant portion of our purchases and are 100% recyclable.%. Insulation materials such as glass wool and recyclable wood. All of these materials are sorted and recycled on our site. A large portion of used cardboard is shredded to serve as packing.

Arcellor Mittal under the brand XCarb® offers low carbon footprint steels.

We are considering the possibility of integrating them into some of our equipment, thus reducing their carbon footprint.

Other avenues are already being tested by ourselves, our customers, and specialized sectors. In all cases, the aim is to increase the lifespan of equipment, which is naturally long.

- Repair: having spare parts available to enable our customers to repair equipment beyond the 7 contractual years.

- Retrofitting: offering parts and solutions (motors, fans, regulators, etc.) to extend the lifespan and improve the performance of the original equipment.

- Reuse: consists of reusing material in its original form without major modification (cleaning, etc.) Already made with spiral ducts, grilles or diffusers for example.

Category 5 - Indirect emissions associated with products sold

This is the category where VIM 's action is most significant. While part of the emissions is linked to the use of the equipment (operating time and conditions, environment, maintenance, configuration, etc.), part is linked to the technologies and components used for their design.

Equipment equipped with motors and fans meets regulations such as ECODESIGN (ErP) whose objective (requirements reviewed periodically) is to reduce electricity consumption and, more broadly, the impact on the environment.

The use of higher efficiency motors (IE2/IE3/IE4) and electronically commutated motors (ECM) has become common in our products.

All motors also accept speed variation when it is functionally advantageous.

Ventilation Units are also concerned with specific performance requirements depending on the type and applications.

This is obviously the case for double flow CTAs with heat exchanger (UVDF) which contribute to recovering energy and reducing their consumption.

The implementation of technologies that help reduce energy consumption affects other products. NOVAX 3D induction hoods allow extraction and introduction flow rates to be reduced by 35% compared to a traditional hood.

Most of our ranges are covered by PEP Eco passport sheets (www.inies.fr) necessary to determine the carbon footprint of the building.

They take into account the entire product life cycle, from the extraction of raw materials to its end of life, not forgetting transport, implementation and the use of the product itself. We periodically work to reduce the environmental impact of our products, including EGES.

Part of our action plan in this category consists of promoting EGES reductions linked to technological modifications or improvements.

All our solutions and ranges for reducing these indirect GHG emissions can be found at en/

Environment

|

|

Social and human rights

- Implementation of safety and health protection procedures

- Regular consultation of staff representative bodies

- Monitoring the frequency and severity rate of work accidents

- Action Plan for Gender Equality - Official Index below:

|

Company with fewer than 250 employees - Score: total = 89

|

- Measures in favor of employment and integration of disabled people (over 6%)

- Action plan in the field of employment and skills management

- Provision of an Individual Social Assessment to employees

- Implementation of numerous social and salary benefits (CET / PES / PEE / PERCO / TR / PPV / IK, etc.)

Ethics and responsible purchasing

|

|