FILTRATION - Standards

NF EN ISO 16890: Classification of general ventilation filters

Context

The classification of filters according to their efficiency is now assessed by the NF EN ISO 16890 standard, which replaced the NF EN 779 standard on July 1, 2018.

It provides better information to professionals and the general public on the real protection that can be expected from filters in relation to fine particles contained in the air taken from outside or inside if the unit with the filter operates in recycling mode.

| PM10 | PM2.5 | PM1 | PM0.1 |

|

|

|

|

| Large particles | Fine particles | Very fine particles | Ultrafine particles |

Upper respiratory tract |

Lower respiratory tract |

Alveoli |

Blood / Whole body |

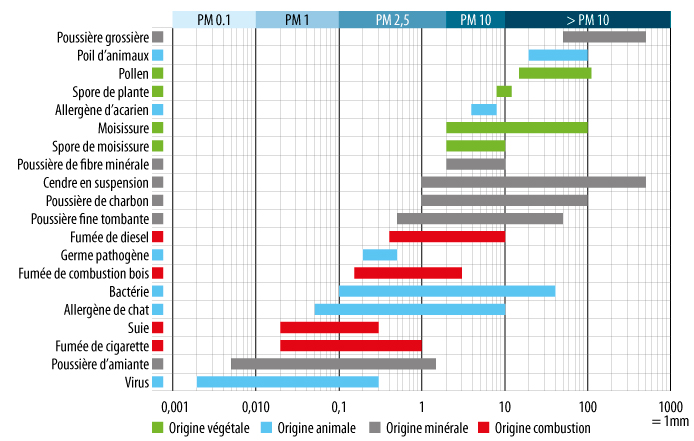

Examples of particle sizes according to their origin

|

Principles of classification

The tests are carried out on particles with a size between 0.3 and 10 μm to define the efficiency -e- on 3 groups: PM1 (particles from 0.3 to 1 μm), PM2.5 (particles from 0.3 to 2.5 μm) and PM10 (particles from 0.3 to 10 μm) To enter a certain category, the filter must capture at least 50% of the corresponding particle size.

If a filter captures more than 50% PM1 particles, it is classified as an ISO ePM1 filter.

If a filter captures less than 50% of PM10 particles, it is classified as a coarse ISO filter.

- ISO ePM1 > ePM1, minimum ≥ 50%

- ISO ePM2.5 > ePM2.5, minimum ≥ 50%

- ISO ePM10 > ePM10 ≥ 50%

- Coarse ISO > ePM10 ≤ 50%, classification based on initial capture

Examples of filter classification by PM

| ISO ePM1 | ISO ePM2.5 | ISO ePM10 |

| ISO ePM1 50% | ISO ePM2.5 50% | ISO ePM10 50% |

| ISO ePM1 55% | ISO ePM2.5 55% | ISO ePM10 55% |

| ISO ePM1 60% | ISO ePM2.5 60% | ISO ePM10 60% |

| ISO ePM1 65% | ISO ePM2.5 65% | ISO ePM10 65% |

| ISO ePM1 70% | ISO ePM2.5 70% | ISO ePM10 70% |

| ISO ePM1 75% | ISO ePM2.5 75% | ISO ePM10 75% |

| ISO ePM1 80% | ISO ePM2.5 80% | ISO ePM10 80% |

| ISO ePM1 85% | ISO ePM2.5 85% | ISO ePM10 85% |

| ISO ePM1 90% | ISO ePM2.5 90% | ISO ePM10 90% |

| ISO ePM1 95% | ISO ePM2.5 95% | ISO ePM10 95% |

Correspondence NF EN 779 and NF EN ISO 16890

| IN 779 | ISO 16890 | |||

| Classes | ePM1 | ePM2.5 | ePM10 | Coarse ISO |

| G3 | - | - | - | ≥ 80% |

| G4 | - | - | - | ≥ 90% |

| M5 | - | - | ≥ 50% | |

| M6 | - | ≥ 50-65% | ≥ 60% | |

| F7 | ≥ 50-65% | ≥ 65-80% | ≥ 85% | |

| F8 | ≥ 65-80% | ≥ 80% | ≥ 90% | |

| F9 | ≥ 80% | ≥ 95% | ≥ 95% | - |

Indicative correspondence table between the 2 classification systems EN 779 and ISO 16890 – No direct correspondence

NF EN 1822-2019: Classification of absolute filters

Principles of classification

Very high efficiency, very low penetration air filters used in ventilation and air conditioning, as well as in technical processes, for example for applications in clean room technology or the pharmaceutical industry, are classified in Europe according to this standard.

The standard defines 3 classes:

- Group E: EPA filters (efficient particulate filters | efficient air filters)

- Group H: HEPA filters (high-efficiency particulate air filters | high-efficiency particulate air filters)

- Group U: ULPA filters (ultra low penetration air filters | very low penetration air filters)

Absolute filters block at least 85% most penetrating particles (MPPS) with a size between 0.1 and 0.3 μm.

The classification indicates the percentage of MPPS particles retained. It ranges from > 85% (class E10) to > 99.999995% (U17 class).

| Overall value | Local value | |||

| Filter class | Performance | Penetration | Performance | Penetration |

| E10 | ≥ 85% | ≤ 15% | - | - |

| E11 | ≥ 95% | ≤ 5% | - | - |

| E12 | ≥ 99.5% | ≤ 0.5% | - | - |

| H13 | ≥ 99.95% | ≤ 0.05% | ≥ 99.75% | ≤ 0.25% |

| H14 | ≥ 99.995% | ≤ 0.005% | ≥ 99.975% | ≤ 0.025% |

| U15 | ≥ 99.9995% | ≤ 0.0005% | ≥ 99.9975% | ≤ 0.0025% |

| U16 | ≥ 99.99995% | ≤ 0.00005% | ≥ 99.99975% | ≤ 0.00025% |

| U17 | ≥ 99.999995% | ≤ 0.000005% | ≥ 99.9999% | ≤ 0.0001% |

NF EN 16798-3-2017: Energy performance and ventilation of buildings / IAQ

Principles

This standard defines different quality levels for outdoor air (ODA: Outdoor Air Quality), the different desired quality levels for indoor supply air (SUP: Supply Air Quality) and the air filtration steps to follow to move from one category to another.

Outdoor air (fresh air) is classified into 3 categories, ranging from ODA 1 where the air is pure except for temporary pollution such as pollen, to ODA 3 where concentrations of both gases and particles are high.

The 3 categories are defined according to the concentrations of particles

and gases compared to the WHO (World Health Organization) guide values

of Health).

| Category | Description | 2005 guide values (WHO) |

| ODA 1 | Clean air likely to be only temporarily dusty (E. pollen) | |

| ODA 2 | Fresh air with a high concentration of particles and/or gaseous pollutants | |

| ODA 3 | Fresh air with a very high concentration of gaseous pollutants and/or particles | > 150% |

The more the pollutant threshold values are exceeded, the more the classification will tend towards ODA 3 classification.

Indoor air quality in human-occupied buildings must take into account expected emissions from indoor sources (human metabolism, activities and processes, building materials, furnishings) and the ventilation system itself to ensure adequate indoor air quality. Possible indoor air categories are:

- SUP 1 Air supplied with a very low concentration of particles and/or gases

- PM2.5 ≤ 10μg/m3 and PM10 ≤ 5μg/m3

- Rooms with strict hygiene requirements such as hospitals, pharmaceutical companies, electronics and optical industries, clean rooms, etc.

- SUP 2 Air supplied with low concentrations of particles and/or gases

- PM2.5 ≤ 5μg/m3 and PM10 ≤ 10μg/m3

- Rooms that are occupied on a regular or permanent basis such as schools and nurseries, offices, hotels, residential buildings, meeting rooms, exhibition and conference rooms, theaters, cinemas, concert halls, etc.

- SUP 3 Air supplied with medium concentrations of particles and/or gases

- PM2.5 ≤ 7μg/m3 and PM10 ≤ 15μg/m3

- Spaces with temporary occupation such as warehouses, shopping centers, laundromats, server rooms, photocopier rooms, etc.

- SUP 4 Air supplied with high concentrations of particles and/or gases

- PM2.5 ≤ 10μg/m3 and PM10 ≤ 20μg/m3

- Rooms with occasional occupancy such as storage rooms, toilets, stairwells, etc.

- SUP 5 Air supplied with very high concentrations of particles and/or gases

- PM2.5 ≤ 15μg/m3 and PM10 ≤ 30μg/m3

- Unoccupied spaces such as garages, data centers, underground parking lots, etc.

The EN 16798 standard defines minimum filtration efficiencies based on outdoor air quality particles and the target indoor air quality level.

| Category | Filter efficiency percentage | ||||

| SUP1 | SUP2 | SUP3 | SUP4 | SUP5 | |

| ODA 1 | 88% | 80% | 80% | 80% | Not specified |

| ODA 2 | 96% | 88% | 80% | 80% | 60% |

| ODA 3 | 99% | 96% | 92% | 80% | 80% |

Following these classifications, the standard defines the filtration levels to be implemented:

In 2018, filter classifications evolved thanks to the arrival of the ISO 16890 standard which replaces the EN 779-2012 standard.

The table on the previous page allows us to suggest equivalences to the old filter classification.

A filter classified as F7 with the old standard may very well be in the ePM10, ePM2.5 or even PM1 category in the new classification, depending on its performance on these different particles.

| Category | Filters to set up | ||||

| SUP1 | SUP2 | SUP3 | SUP4 | SUP5 | |

| ODA 1 |

M5+F7+ activated carbon recommended |

80% | 80% | 80% | Not specified |

| ODA 2 | F7+F7+ activated carbon | M5+F7+ activated carbon | 80% | F7 | M5 |

| ODA 3 | F7+F9+ activated carbon | F7+F7+ activated carbon | M5+F7+ activated carbon | F7 | F7 |

NF EN 13053-2019: Ventilation of non-residential buildings / Air handling units

Filters installed in air handling units used for occupied premises must be tested and classified in accordance with standard NF EN ISO 16890.

The European standard NF EN 13053-2019 defines requirements in terms of filtration:

- ISO ePM1 50 efficiency% according to ISO 16890 is a minimum requirement for supply air

- Pressure drops for filter replacement.

Double Flow CTA with exchanger / NRVU-BVU

- When blowing: Minimum fine filter ISO ePM1 50% on the air inlet side

- On resumption: Minimum pre-filter ISO ePM10 50% on air extraction

Single Flow CTA / NRVU-UVU

- When blowing: Minimum fine filter ISO ePM1 50%

Filter installation recommendations

- The first stage of filtration must be installed as close as possible to the fresh air inlet opening. Additional “coarse” filters are permitted.

- The second stage of filtration is placed on the outlet side, at the start of the supply duct in order to keep the duct network clean.

- If the filtration system has only one stage as in the case of an air supply system, a minimum ISO ePM1 50 filter% must be installed.

Recommended final pressure drop according to the standard

The pressure drop of a filter section loaded with dust must not exceed the values given in the following table. Lower final pressure drops may be specified.

| Filter class | Recommended final pressure drop (Pa) |

| ISO coarse (rude) |

Initial pressure drop +50 Pa or Initial pressure drop x3 (whichever is lower) |

|

ISO ePM1 ISO ePM2.5 ISO ePM10 |

Initial pressure drop +100 Pa or Initial pressure drop x3 (whichever is lower) |