TECHNICAL INFORMATION

IP / AF / IK protection ratings

Euroclass fire resistance

Corrosive environments: materials and protection

Aerodynamic and acoustic concepts

SFP Specific Fan Power Classification

The pSFP or SFP (Specific Fan Power) is a coefficient from the EN 13779 standard (Ventilation in non-residential buildings - Performance requirements for ventilation and air conditioning systems), which allows the overall energy efficiency of a fan or ventilation system to be qualified.

The SFP is the ratio between the power input and the flow rate of the fan or ventilation system:

| SFP = P/Qv | P = power absorbed in W |

| Qv = flow rate in m3/s | |

| SFP = W/m3.s-1 |

The SFP is therefore calculated for each flow/pressure point of the fan curve.

The lower the SFP, the more energy efficient the fan.

Fans or ventilation systems can thus be compared and classified according to a table from the EN 13779 standard.

| SFP classification table | |

| Category | Minimum fresh air flow rate per occupant (in m3/h) |

| SFP 1 | |

| SFP 2 | 500 - 750 |

| SFP 3 | 750 - 1250 |

| SFP 4 | 1250 - 2000 |

| SFP 5 | 2000 - 3000 |

| SFP 6 | 3000 - 4500 |

| SFP 7 | > 4500 |

The pSFP or SFP is sometimes expressed in kW/m3.s-1.

This concept of SFP is indicated on the flow/pressure curves as they are updated.

IP / AF / IK protection ratings

The NF C 15-100 standard lists and codifies the external influences to which an electrical installation may be subjected: presence of water, presence of solid bodies, risks of shocks, vibrations, presence of corrosive substances.Different indices make it possible to characterize the behavior of products in relation to these influences:

- IP, Protection Index: specifies the resistance of the material against the penetration of solid foreign bodies and against the penetration of water with harmful effects.

- Protection index that specifies the material that protects people from access to dangerous parts.

- AF: specifies the resistance of the material against the presence of corrosive or polluting substances.

- IK: specifies the resistance of the material against mechanical shocks.

Note: Protection against explosion hazards or conditions such as moisture, corrosive vapors, fungi or vermin are not represented by these ratings.

These protection ratings are product-specific. For them to be extended to the rest of the installation, the device must be properly integrated, ensuring that the original level of protection is maintained.

IP PROTECTION RATING

Meaning of the last two characters of the IPxy protection rating

- x characterizes the protection of the material against the penetration of foreign solid bodies.

- It characterizes the protection of the material against the penetration of water with harmful effects.

| 1er figure Protection against solid bodies |

||

| 1 |  |

Protected against solid bodies greater than 50mm |

| 2 |  |

Protected against solid objects larger than 12.5mm |

| 3 |  |

Protected against solid bodies larger than 2.5mm |

| 4 |  |

Protected against solid bodies larger than 1mm |

| 5 |  |

Protected against dust (no harmful deposits) |

| 6 |  |

Completely protected against dust |

| 2th figure Protection against solid bodies |

||

| 1 |  |

Protected against vertically falling water drops (condensation) |

| 2 |  |

Protected against water drops falling up to 15° from the vertical |

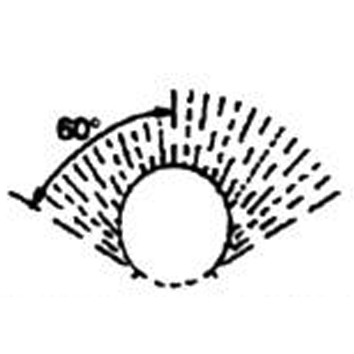

| 3 |  |

Protected against rainwater up to 60° from the vertical |

| 4 |  |

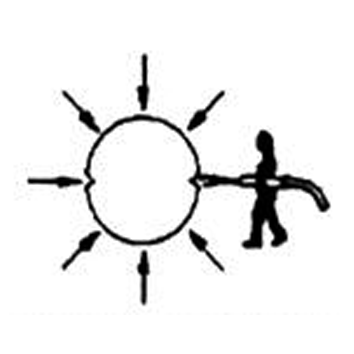

Protected against water splashes from all directions |

| 5 |  |

Protected against water jets from all directions using a hose |

| 6 |  |

Protected against water projections similar to sea spray |

| 7 |  |

Protected against the effects of temporary immersion |

| 8 |  |

Protected against the effects of permanent immersion |

Special case

Resistance to water penetration due to high pressure cleaning (Karcher) is specified by the IPx9K index.

- PERSONAL PROTECTION INDEX AGAINST ACCESS TO DANGEROUS PARTS

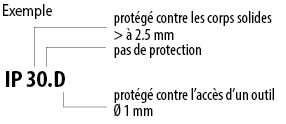

It is completed with a final letter Z, the IPxyZ code. It is used when the actual protection of people against access to dangerous parts is better than that indicated by the first digit x of the IPxy index.

When only the protection of persons is of interest to specify, the two characteristic figures of the IP are replaced by X.

Example: IP XXB.

Designation letter:

HAS protected against access from the back of the hand

B protected against finger access

C protected against access by a Ø2.5 mm tool

D protected against access by a Ø1 mm tool

AF PROTECTION INDEX AGAINST CORROSIVE OR POLLUTING SUBSTANCES

The practical guide UTE C 15-103 defines the AF protection class taking into account the presence of corrosive or polluting substances.

The absence of an indication means that the external influence class is AF1 (negligible risk of corrosive or polluting substances).

- AF2: atmospheric agents.

- AF3: intermittent or accidental presence.

- AF4: permanent presence of corrosive or polluting substances.

The NF C 15-100 standard, 2002 edition, gives the operating conditions and deals more specifically with class AF.

IK MECHANICAL SHOCK PROTECTION INDEX

The NF C 20-010 standard defines the degree of protection against mechanical shocks, symbolized by a characteristic number following the two figures of the IP degrees.

It is the subject of a European standard project EN 50-102 to define an IK code.

The tables on the following pages present the degrees of protection of the enclosures and take into account the equivalences between the old third digits of the IP code of the NF C 20-010 (1986) standard and the IK code.

| Mechanical impact protection indices IK | |

| Impact energy (joules) | IK code according to standard NF EN 50102 |

| 0.00 | 00 |

| 0.15 | 01 |

| 0.2 | 02 |

| 0.35 | 03 |

| 0.5 | 04 |

| 0.7 | 05 |

| 1 | 06 |

| 2 | 07 |

| 5 | 08 |

| 10 | 09 |

| 20 | 10 |

EUROCLASSES fire resistance

Two fire reaction classification systems coexist in French legislation:- The unified European classification of products called EUROCLASSE

- The old French classification of incombustible, M0, M1...

The European classification system includes 7 Euroclasses:

- A1 and A2: non-combustible product.

- B: low-combustible product.

- C: combustible product.

- D: highly combustible product.

- E : highly flammable and flame-spreading product.

- F: unclassified or untested product.

And an additional classification for fumes and drops (or particles).

Two additional classifications relating to the production of smoke on the one hand, and of flaming drops or particles on the other, complete the main Euroclass, with the exception of Euroclass A1.

Each additional ranking includes 3 levels:

| SMOKE opacity class* | ||

| s1 | s2 | s3 |

| Low quantity and speed of release | Average release quantity and speed | High quantity and speed of release |

| Class of Flaming PARTICLES* | ||

| d0 | d1 | d3 |

| No dripping or flaming debris | No drops or debris whose inflammation lasts more than 10 seconds. | Neither d0 nor d1 |

* These measurements are carried out according to standardized tests

EUROCLASS EQUIVALENCES / OLD CLASSIFICATION

Pending a review of fire safety regulations taking into account the integration of Euroclasses, a table published in the Official Journal makes it possible to make the link between the regulatory requirements expressed with M classifications and the Euroclasses already applied to products.

| Table of equivalences | |||

| Euroclass of the product to be implemented | Additional requirement | ||

| A1 | - | - | Fireproof |

| A2 | s1 | d0 | M0 |

| A2 | s1 | d1 | M1 |

| A2 | s2 s3 |

d0 d1 |

|

| B | s1 s2 s3 |

d0 d1 |

|

| C | s1 s2 s3 |

d0 d1 |

M2 |

| D | s2 s3 |

d0 d1 |

M3 M4 (Non-dripping) |

| Anything other than E-d2 and F | M4 | ||

Corrosive environments: materials and protection

GENERAL INFORMATION

Corrosive environments can more or less quickly damage ventilation equipment, such as fans, networks, terminals, etc., or the components (motors, turbines, pulleys, screws, electrical accessories, etc.) that make them up. A corrosive environment includes the outside atmosphere, the inside environment, and the gases carried by the ventilation system. A fan by the sea will be exposed to both the outside air and the aggression of the salt air drawn in by the ventilation system.

| CLASSIFICATION OF ENVIRONMENTS | ||

| Corrosivity category | Outside | Interior |

| C1 very weak | - | Clean atmosphere heated buildings |

| C2 weak | Atmospheres with low pollution levels: mainly rural areas. | Poorly heated buildings where condensation may occur |

| C3 average | Urban and industrial atmospheres, moderate sulfur dioxide pollution; low salinity coastal areas |

Production premises with high humidity and some air pollution |

| C4 high | Industrial zones and coastal areas in moderate salinity. |

Chemical plants, swimming pools, coastal vessels, shipyards... |

| C5 very high | Industrial areas with high humidity and aggressive atmosphere. Coastal areas with high salinity |

Buildings or areas with near-permanent condensation and high pollution |

| C5-m very high (navy) |

High salinity offshore areas; areas industrial with extreme humidity and an aggressive atmosphere; atmospheres tropical and subtropical |

Industrial premises with extreme humidity and aggressive atmosphere |

| SUSTAINABILITY | |

| WEAK | Up to 7 years old |

| AVERAGE | From 7 to 15 years old |

| HIGH | from 15 to 25 years old |

| VERY HIGH | Over 25 years old |

According to standard NF EN ISO 12944-2

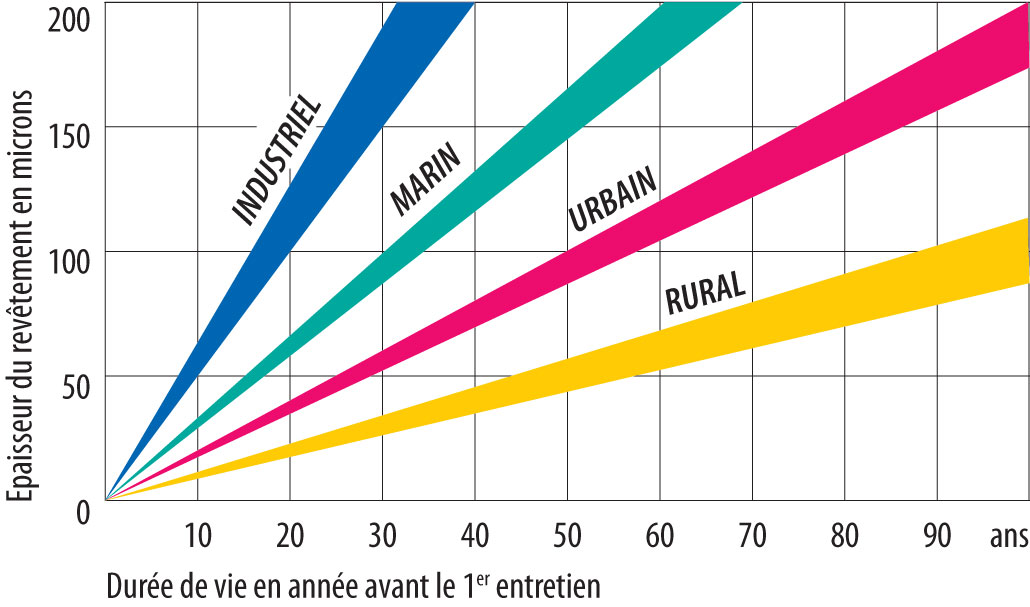

Durability is defined by the NF EN ISO 12944-1 standard as the expected lifespan of a system protected by paint until the first major maintenance operation. Durability is a technical parameter that can help build a maintenance plan. Durability is not a guaranteed duration.

VIM MATERIALS: MAIN MATERIALS - PROCESSING OPTIONS

- GENERAL INFORMATION

It is advisable to carefully read the descriptions of the materials in the catalogs and instructions, to determine whether the material and its treatment are suitable for the environment, the application and the desired durability. As standard, most of our products are designed for installation indoors (corrosivity category C1 or C2) or outdoors (corrosivity category C2). Some product ranges are designed to meet the needs of more corrosive environments. The casing of our AHUs, commonly installed outdoors, is made of pre-painted steel or alloy-coated steel that allows installation in environments with a corrosivity category of C4 or even C5. This is the case, for example, of VSA and VSB fans in PPH or diffusers or terminals in ABS.

- STAINLESS STEEL

NOVAX and VORAX range hoods are made of AISI 304 L stainless steel. AISI 304 L stainless steel is suitable for standard professional kitchens. In industrial or food processing applications, it is sometimes necessary to choose 316 L or another grade depending on the food products being processed.

| TYPE OF STAINLESS STEEL | ||||

| AISI | ISO/EN designation | Noticed | Classic applications | Food compatibility |

| 304 | X2CrNi18-10 / 1.4301 | Standard | Food industries / Standard professional kitchens | Yes |

| 304L | X2CrNi18-9 / 1.4307 / (Carbon | Low carbon | Food industries / Standard professional kitchens | Yes |

| 316 | X5CrNiMol17-12-2 / 1.4401 | With Molybdenum | Pharmaceutical, petrochemical, chemical, beverage, silo industries / Acid/salty food industries, dairies, fishmongers | Yes |

| 316L | X5CrNiMol17-12-2 / 1.4404 / (Carbon |

Low carbon - With Molybdenum |

Pharmaceutical, petrochemical, chemical, beverage, silo industries / Acid/salty food industries, dairies, fishmongers | Yes |

Note: In screws we speak of A2 or A4.

A2 = AISI 304 or 304L. A4 = AISI 316

| TYPE OF STAINLESS STEEL | |||

| Range | Product | AISI 304 stainless steel | AISI 316L stainless steel |

| REMV | Circular registers | ▪️ | ▪️ |

| REEV | Circular registers | ▪️ | ▪️ |

| REIC | Iris Registers | ▪️ | |

| RDGC | CAV circular registers | ▪️ | ▪️ |

| CDR 50 | Rectangular registers | ▪️ | ▪️ |

| CDR 100 | Registers rectangular | ▪️ | ▪️ |

| CDRE 200 | Registers rectangular | ▪️ | ▪️ |

| RDGR | Registers rectangular CAV | ▪️ | ▪️ |

| BISR | Low-speed terminals | ▪️ | |

| GCPI | Low-speed terminals | ▪️ | |

| GMAI | Exterior grilles | ▪️ | ▪️ |

| SIL GA | External acoustic grilles | ▪️ | ▪️ |

| SIL OPTIMUM 50 | Circular silencers | ▪️ | ▪️ |

| SIL OPTIMUM 100 | Silent circulars | ▪️ | ▪️ |

| SIL RBS+ | Rectangular silencers | ▪️ | ▪️ |

| SIL RBD + | Silent rectangular | ▪️ | ▪️ |

| DCRS A - DCRD A + Plenum | Circular diffusers | ▪️ | |

| DAFR DF + Plenum | Diffusers slotted square | ▪️ | |

| DJHR - DJHC - DJHD + Plenum | Swirl diffusers - fixed blades | ▪️ | |

| DJHM - DJHMO | Diffusers with helical jet - adjustable vanes | ▪️ | |

If you have any doubts or questions, please contact our sales teams, providing all the precise information on the application and the environment of the equipment.

- GALVANIZED STEEL - ZINC (ZN)

| The sheets and strips commonly used by VIM to manufacture boxes, fans, spiral ducts and network accessories are hot-dip galvanized steel (S250GD) Z275 compliant with EN 10142. This means that the steel is covered with a layer of Zinc of 275 g/m2, i.e. a coating of 20 microns per side. Its maximum operating temperature is 200°C continuously and 250°C at peak. Beyond these temperatures, the adhesion of the zinc is impaired, which reduces the corrosion resistance. This type of steel is suitable for environments classified C2 with high or very high durability, or C3 with lower durability. For environments of type C4 or C5, it is advisable to choose another material (Alu / Stainless steel / other) or to plan a paint treatment. | Galvanizing life in an outdoor environment |

White rust on galvanized steel

This is zinc hydroxide that forms under the action of moisture in the absence of ventilation. For example, when fans / boxes wrapped in plastic film to protect them during transport become damp and are not unpacked. While these stains affect the appearance, they do not affect the life and strength of the zinc coating. To remove them, the first action is to scrub with a stiff nylon bristle brush. They can be washed with a 10% acetic acid solution.% and rinsed. This treatment may remove some of the metallic luster.

- METAL COATED STEEL - ZAM ALLOY (ZN-AL-MG)

These steels provide better corrosion resistance than galvanized steel for identical weights. They provide self-repairing protection for the edges.

This is the case of S250GD + steel ZM310 (310 g/m2 coating on both sides).

Its corrosion resistance is much better than Z275 and allows its application in environments with corrosivity category C4 with high durability and C5 with low or medium durability depending on the applications and suppliers.

It is particularly suitable for environments with high SO2, high chlorine or high ammonia.

This type of steel is an alternative to the use of other materials or anti-corrosion treatment such as paint.

This type of coating is used on some of our CTAs and on the JBRB ECOWATT range of 400°C 30 min VMC units.

- PRE-PAINTED STEEL GRANITE® HDXTREME ARCELOR

In this configuration, the steel (S250GD + Z275) is coated on the outside with a 3-layer coating of 70 microns and on its inside with a 12 micron support layer.

Granite® HDXtreme combines the best UV and corrosion protection with durability and a unique finish.

It has been developed to guarantee a long service life in very harsh environments, particularly at the seaside.

Its UV resistance places it in the RUV5 category and its corrosion resistance in the RC5+ category according to standard EN 10169, authorizing its use in C5 environments with average durability.

- VIM TREATMENT OPTIONS TO IMPROVE CORROSION RESISTANCE

For certain ranges of ventilation boxes and turrets, we have defined several treatment options depending on their use, the nature of the environment, and the desired durability. These may concern the casing, the fan, the motor, or the screws, depending on the case. Precise information on the composition of standard components and the nature of the treatment of the different options is available for each product sheet on en/

- F400 boxes: KDT/KCTR/KUBAIR

- C4 boxes and ventilation: JBRB ECOWATT /KSH

- F400 Turrets: TED/TCD

For other products, please contact us.