KSDE ECOWATT®

Simple flow AHU

Compact - Reaction - ECM < 24,000 M3/h

KSDE ECOWATT®

New product

| Compliant ErP 2018 - UVNR |

Filters

|

||||

- Communicating Modbus and BACnet control

- High level of finish and performance

- Free-wheeling fan with reaction

- Double skin rock wool insulation 50 mm

- Low consumption ECM motor

Application

Introduction of fresh air, heating and/or cooling.

Indoor or outdoor installation.

Treated air temperature -25 to +40°C.

-

Description

-

Dimensions

-

Documentation

-

Public Price

-

Software

-

References

5 single-block sizes 40 / 55 / 75 / 95 / 120 and 2 double-block sizes 160 and 200.

9 models according to the types of integrated batteries:

| Electric | Hot water | Cold water | Reversible water | Direct relaxation | |

| EI | ■ | ||||

| EIX | ■ | ■ | |||

| EIF | ■ | ■ | |||

| EC | ■ | ||||

| ER | ■ | ||||

| ECF | ■ | ■ | |||

| EX | ■ | ||||

| ERC | ■ | ■ | |||

| ERR | ■ x2 |

Configurations:

- Exterior with roof mounted:

- EXD : easement on the right,

- EXG : easement on the left.

- Interior without roof:

- D: easement on the right,

- G: easement on the left.

Regulation:

- VIM specific integrated CORRIGO automaton.

- 3 operating modes: variable flow (VAV), constant flow (CAV), constant pressure (COP).

- Communicating Modbus RTU on RS485 port or Modbus TCP/IP, BACnet IP or MSTP.

- ETD2 remote touch control.

- KSDE CMI insulated mixing box.

Description :

- Classification according to EN 1886: D1/L2/F9/T2/TB2 (TUV tests)

- In-line construction, connection by rectangular tapping.

- Interior and exterior made of alloy steel (Zn-Al-Mg) ZM310, corrosion resistance C5.

- Self-supporting structure in 50 mm double-skin panels.

- Insulation with mineral rock wool, thickness 50 mm, density 40 kg/m3,

- Thermal conductivity 0.037 W/(mk) (20/80°C).

- Fire classification A1 according to standard EN 13 501.1.

- Metallic freewheel type reaction fan (incombustible A1) associated with an electronically commutated ECM motor.

Switch mounted/wired. - Frame made of ZM310 alloy steel, 3 mm thick.

- Access doors to the main components mounted on hinges, opening by 1/4 turn screw.

- Motorized sealed register inside the CTA :

- Dual function: antifreeze protection of water batteries and response to article CH 38 of the fire regulations in ER

Motorization

- Three-phase motor with integrated electronic protection:

- KSDE 55 / 75 / 160: Tri 400 V, 50/60 Hz, IP54, class B.

- KSDE 40 / 95 / 120 / 200: Tri 400 V, 50/60 Hz, IP55, class F.

Filtration

- Filters supplied as standard: FIFI M5 ePM10 50 mini-pleat filters%.

- Additional filters available as an option:

- HPE FIFI F7 ePM1 55 Mini-Pleat Filters%.

- HPE FIFI F9 ePM1 80 Minipleat Filters%.

- Additional options in sizes 160 and 200:

- FIFI F7 ePM1 60 bag filters%.

- FIFI F7 ePM1 55 Dihedral Filters%.

- FIFI F9 ePM1 85 bag filters%.

- FIFI F9 ePM1 80 dihedral filters%.

Regulation

- CORRIGO regulation mounted/wired, integrated into the unit in a dedicated compartment, with remote touch control, allowing 3 operating modes:

| FLOW RATE SETTINGS | RECOMMENDED APPLICATIONS |

| VAV MODE - VARIABLE FLOW | |

| Fan speed variation | |

| - Flow rate depending on a 0-10 V signal from the extraction, the remote control, an external probe (CO2, temperature, humidity, etc.) or a remote control (M/A + variation). | - Compensation, controlled by a kitchen extraction, - Single-zone installations, requiring adaptation of ventilation depending on occupancy. |

| CAV MODE - CONSTANT FLOW | |

| Fan speed set to a specific flow rate | |

| - Manual entry (m3/h) of 3 flow rate settings type 0-PV-GV-BOOST. Manual operation or on time slot. - Visualization of values on the display, manual switching, by clock or external contact. |

- Installations requiring control of one or more specific flow rates. |

| COP MODE - CONSTANT PRESSURE | |

| Automatic fan speed variation to maintain constant pressure | |

| - Constant pressure value measured by an external probe (option) located in the blowing duct network. | - Multi-zone installations, associated with modulation of terminal flow rates. |

KSDE delivered in CAV mode, without accessories.

EI / EIX / EIR electric batteries

- 304L stainless steel resistors.

- Safety thermostats: one thermostat with automatic reset, one thermostat with manual reset.

- Pulse train control.

- Post-ventilation.

- Load shedding control possible depending on battery characteristics: total load shedding for 1-stage batteries and partial or total load shedding for 2-stage batteries.

- The 400V three-phase power supply of the electric battery is separate from the main power supply, regulation and fan(s).

Hot water/reversible batteries EC / ECF / ER / ERC / EIR

- 2, 3, 4, 6 or 8 row battery depending on the model, with copper tubes, aluminum fins, galvanized steel frame; threaded connection tubes.

- Right or left connection in the direction of air flow.

- Frost protection by contact probe.

- Battery(ies) mounted on slide accessible via side hatch.

- Stainless steel condensate tray and droplet separator for reversible versions.

- Motorized 3-way valve (24V) proportional by signal (0-10V), optional, not mounted.

EX direct expansion battery / EIX electric direct expansion battery: sizes 40 to 120

- Reversible battery 1 or 2 circuits on 4 rows for operation as a condenser or evaporator; copper tubes and collectors, aluminum fins, galvanized steel frame. Stainless steel condensate recovery tray and droplet separator.

- Provide a CTA kit with the direct expansion unit (not supplied) equipped with its own probes and temperature regulation system. In the case of a direct expansion battery, the CORRIGO regulator manages, apart from the preheating temperature on EIX models, only the ventilation and does not manage the temperature regulation at the DX battery outlet.

- EIX version: preheating of the direct expansion battery with electric battery. Control, set point and post-ventilation of the preheating battery provided by the Corrigo.

- COP mode regulation not compatible with a direct expansion battery.

CMI Mixing Box

- 1 or 2-way mixing module equipped with motorized register(s) and temperature probe(s).

- Identical construction to KSDE with interior and exterior versions.

- CTA suction assembly.

- The 1-way module allows you to change the orientation of the fresh air intake.

- The 2-way module allows mixing of fresh air and indoor air depending on the CO2 level or temperature or for recycling.

- The control of the motorized registers is ensured by the KSDE regulation.

- Possible choices of positions for fresh air and return air intakes

Air treatment selection

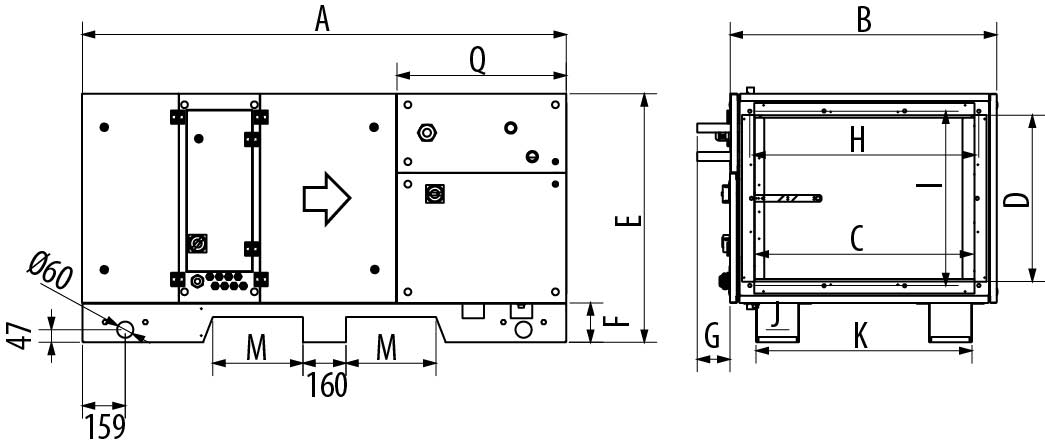

Interior model 40 to 120

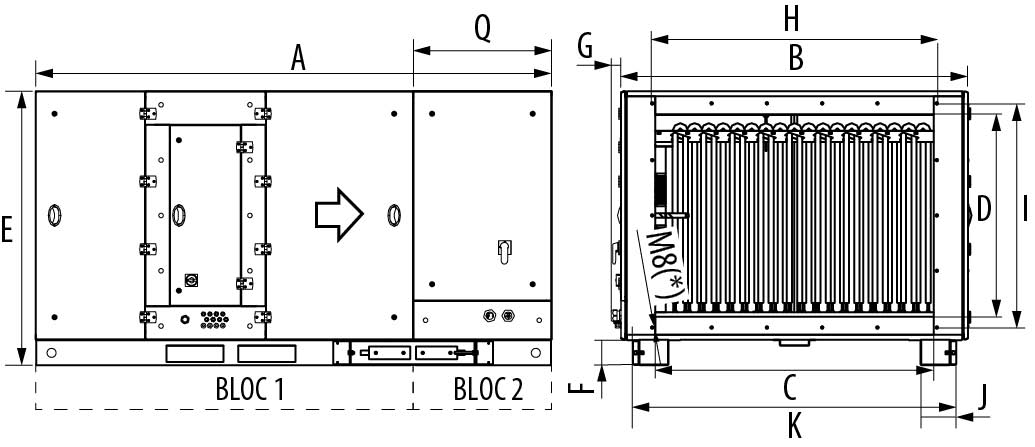

Interior model 160 - 200

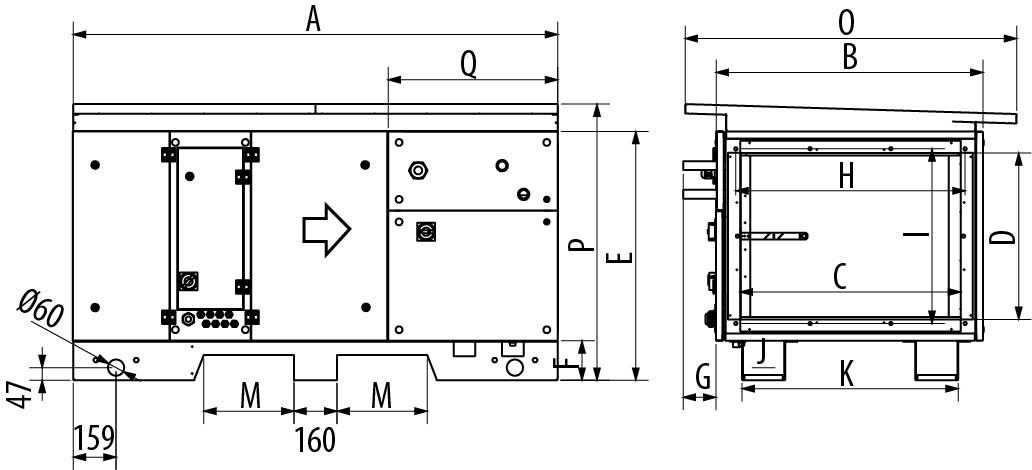

Outdoor model 40 to 120

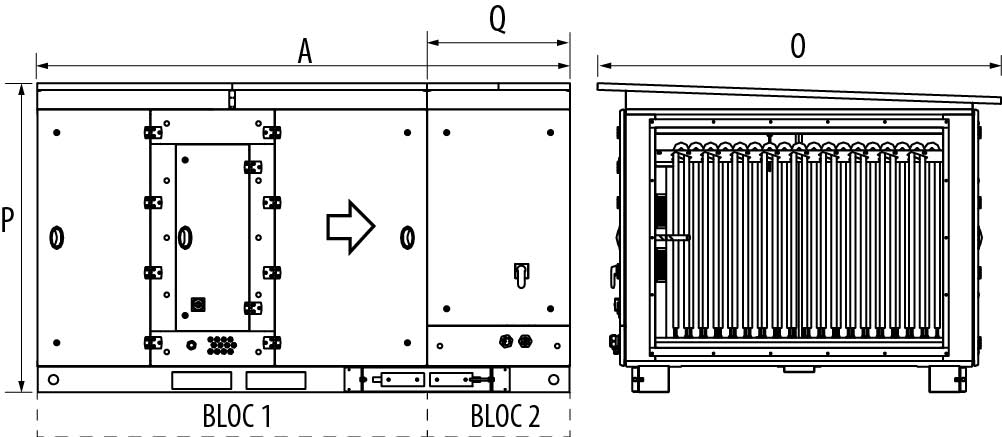

Outdoor model 160 - 200

| Sizes | A | B | C | D | E | F | G (except EI) | G (EI) | H | I | I | K | M | O | P | Q |

| 40 | 1774 | 716 | 546 | 546 | 850 | 155 | 120 | 54 | 574 | 574 | 160 | 570 | 322 | 955 | 950 | 585 |

| 55 | 1800 | 991 | 820 | 620 | 925 | 155 | 120 | 54 | 840 | 650 | 160 | 803 | 335 | 1232 | 1026 | 630 |

| 75 | 1864 | 988 | 820 | 830 | 1162 | 155 | 120 | 54 | 840 | 850 | 160 | 803 | 347 | 1232 | 1264 | 664 |

| 95 | 2000 | 1300 | 1094 | 830 | 1162 | 155 | 120 | 54 | 1140 | 850 | 160 | 1109 | 435 | 1541 | 1282 | 695 |

| 120 | 2350 | 1300 | 1094 | 1100 | 1460 | 155 | 120 | 54 | 1140 | 1150 | 160 | 1109 | 400 | 1541 | 1575 | 750 |

| 160 | 2800 | 1610 | 1210 | 1160 | 1485 | 140 | 100 | 65 | 1240 | 1216 | 160 | 1380 | - | 1820 | 1615 | 750 |

| 200 | 2800 | 1950 | 1515 | 1160 | 1485 | 140 | 100 | 65 | 1545 | 1216 | 160 | 1688 | - | 2120 | 1625 | 750 |

| Sizes | KSDE weight (kg) | |||||||||||||||

| Interior model - Without roof | Exterior Model - With roof | |||||||||||||||

| EI | EIX / EIF | EC | ER | EX | ECF | ERC | ERR | EI | EIX / EIF | EC | ER | EX | ECF | ERC | ERR | |

| 40 | 285 | 307 | 249 | 264 | 256 | 271 | 279 | 286 | 307 | 329 | 271 | 286 | 278 | 293 | 301 | 308 |

| 55 | 328 | 356 | 295 | 314 | 304 | 323 | 333 | 342 | 355 | 383 | 322 | 341 | 331 | 350 | 360 | 369 |

| 75 | 392 | 431 | 367 | 391 | 378 | 406 | 419 | 430 | 420 | 459 | 395 | 419 | 406 | 434 | 447 | 458 |

| 95 | 456 | 504 | 436 | 479 | 450 | 484 | 513 | 527 | 491 | 539 | 471 | 514 | 485 | 519 | 548 | 562 |

| 120 | 516 | 579 | 505 | 563 | 524 | 568 | 607 | 626 | 557 | 620 | 546 | 604 | 565 | 609 | 648 | 667 |

| 160 | 671 | 732 | 655 | 772 | 687 | 732 | 817 | 844 | 719 | 780 | 703 | 820 | 735 | 780 | 865 | 892 |

| 200 | 881 | 952 | 876 | 1017 | 907 | 963 | 1073 | 1100 | 938 | 1021 | 933 | 1074 | 964 | 1020 | 1130 | 1157 |

Detailed specifications

Detailed specifications

Text catalog pages (CT)

Catalog Pages - Other

Public tariff price

Public tariff price

Price catalog pages (CP)

Installation instructions

Installation instructions

Installation instructions (NT)

Fire / Smoke extraction certificates

Fire / Smoke extraction certificates

Fire classification report (PVFEU)

Performance / Environment Certificates

Performance / Environment Certificates

ErP regulatory sheet (FERP)

Declaration of performance (DOP)

Product environmental profile (PEP)

Electrical / ATEX Certificates

Electrical / ATEX Certificates

Electrical CE Declarations (DCCE)

Prescription assistance

Prescription assistance

Specification text (TP)

Commercial documents

Commercial documents

Commercial leaflet (FCOM)