DPSR 4D

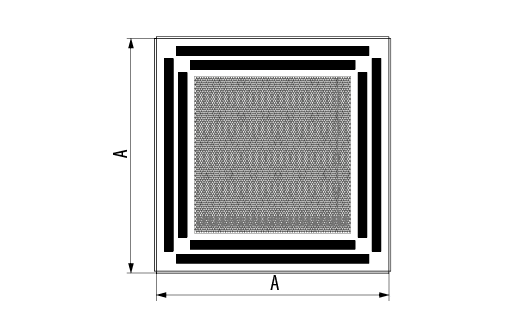

Square diffusers

Combined return air blowing - Slabs

View larger

View larger

DPSR 4D

New product

- Combined air supply and return

- Adapted to variable flow rate

- Model for 600x600 slab

- Neat aesthetics with a matt RAL 9003 finish

- Possible filtration on recovery

Application

Air conditioning, heating, ventilation.

Allows the combination of two functions in a single diffuser.

Air diffusion is carried out by 4 lateral linear diffusers and recovery by the perforated central part which can accommodate a filter (option).

-

Description

-

Dimensions

-

Documentation

-

Public Price

-

Software

-

References

- DPSR 4D: diffuser with bare plenum.

- DPSR 4D I: diffuser with insulated plenum.

Description

- Diffuser with fixed quadrilateral linear slots allowing blowing in 4 directions.

- Diffuser in painted steel in matt RAL9003 color.

- Available in 1, 2 and 3 blow slots.

- Removable central core in perforated sheet metal allowing the installation of a filter.

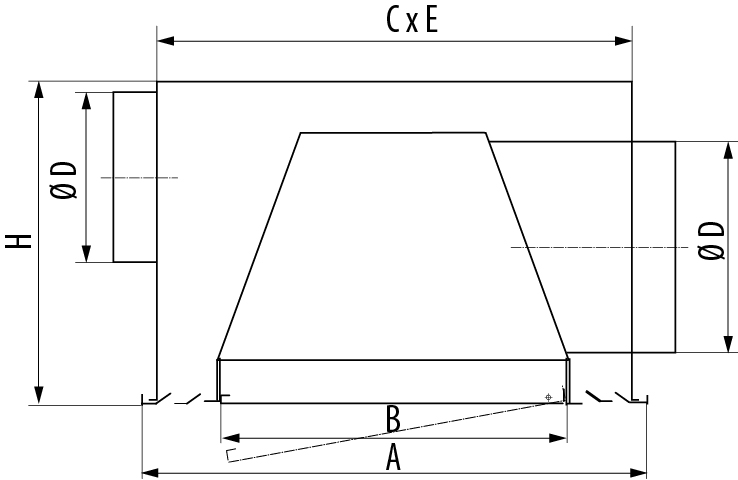

- Supplied with double compartment plenum in galvanized steel with PH horizontal tappings, insulated or non-insulated.

- Other RAL: contact us.

| Model | A x A | C x E | Ø D | H | FIGR |

| DPSR 4D 1F | 594 x 594 | 580 x 555 | 250 | 378 | 460 x 460 x 5 |

| DPSR 4D 2F | 594 x 594 | 580 x 555 | 250 | 380 | 390 x 390 x 5 |

| DPSR 4D 3F | 594 x 594 | 580 x 555 | 250 | 380 | 320 x 320 x 5 |

Detailed specifications

Detailed specifications

Text catalog pages (CT)

Public tariff price

Public tariff price

Price catalog pages (CP)

Installation instructions

Installation instructions

Technical data (DTEC)

| BROADCASTING | ||||

|

Selection of GRADA grilles and diffusers |

|

GRADA designation MSH01 DA340 CC600 DS170/DR170 DC560 WS230/WS230P WS400 WR230 HD600 EG400PF/EG400-F CS400 TS600 TE370 TE750 AD130-F/GD130-F AD100-F/GD100-F SF130 AD600 BD640 AG300/AG320 JD130/JD120/JD110 JD170/JD160/JD150 SLF SLS CB400 |

VIM designation DABR GD DATI DCDU DCFD/DCFS DDTI DJHC/DJHD DJHE DJHR DLFF B DPCD/DPCS AB DPDU DPFF A PH/PHI DPSR 2D/2DI DPSR 4D/4DI GADD A/GADD F GASD A/GASD F GCDD FG GLBF GLBF AF GSBF A/GSBF AI JDLP C/F/G JDSP C/F/G SLF SLS GCBI |