UTBS ECOWATT - UTBS ECOWATT PRO-REG

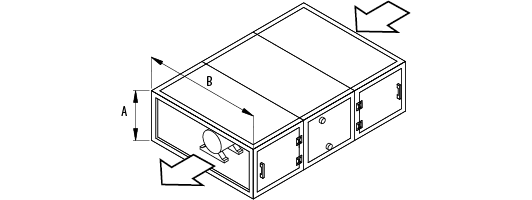

Simple flow AHU

Ceiling AHU - Backward - ECM < 8000 m3/h

UTBS ECOWATT - UTBS ECOWATT PRO-REG

New product

| ErP 2018 UVNR compliant Variable EC motor |

Filters

|

||||||

- Extra flat central unit: height 360 to 500 mm

- Freewheel fans and low-power ECM motor

- Double skin 25 mm glass wool insulation

- Envelope suitable for C5 environments

- Flow rates from 500 to 8,000 m3/h

- Indoor and outdoor version

Applications:

Introduction of fresh air, heating, air conditioning.

Indoor or outdoor installation.

Floor or ceiling mounting.

Vertical mounting for models without cold battery.

-

Description

-

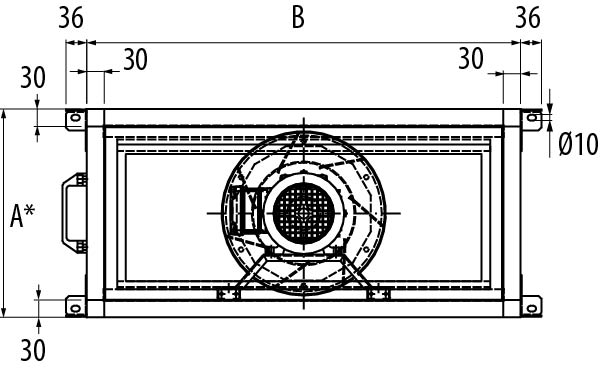

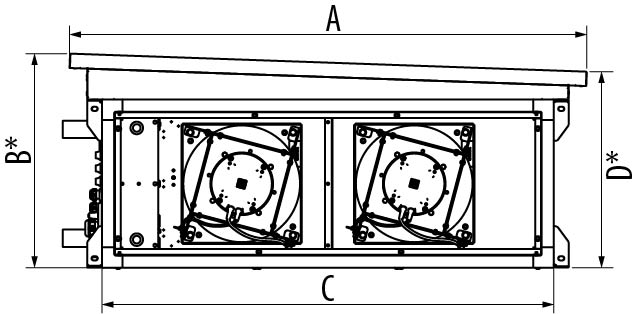

Dimensions

-

Documentation

-

Public Price

-

Software

-

References

4 sizes:

- Size 2: height 360 mm

- Sizes 3 and 5: height 410 mm

- Size 8: height 500 mm

- 750 mm long module with a filtration stage

- 969 mm long module with two filtration stages

| Battery Type | |||||

| Electric | Hot water | Cold water | Reversible water | Direct relaxation | |

| EI | ■ | ||||

| EIF | ■ | ■ | |||

| EC | ■ | ||||

| ER | ■ | ||||

| ECF | ■ | ■ | |||

| EX | ■ | ||||

Configurations:

- Interiors without roof, without support frame: D right easement - G left easement.

- Interiors without roof, with support frame: DB right servitude - GB left servitude.

- Exterior with roof, without support frame: EXD right easement - EXG left easement.

- Exterior with roof, with support frame: EXDB right servitude - EXGB left servitude.

Additional modules:

- CM: 2-way mixing modules.

- SIL: 750 mm silencer.

- PB: plenum.

- CB: battery box.

UTBS ECOWATT

- Unregulated CTA, only equipped with a REB ECOWATT flow adjustment potentiometer.

UTBS ECOWATT PRO-REG

- CTA with wired mounted regulation, 3 operating modes:

- Variable flow (VAV)

- Constant flow rate (CAV)

- Constant pressure (COP)

- Regulation by CORRIGO integrated automation specific to VIM .

- Communicating ModBus RTU on RS485 port or ModBus TCP/IP, BACnet IP or MSTP.

- ETD2 remote touch control.

Construction

- Modular structure in aluminum profile.

- Online construction.

- Smooth rectangular flanges supplied with the main module.

- Kit for fixing the modules together, consisting of a seal and 4 sets of screws, nuts and washers.

- Exterior finish: pre-painted galvanized steel, dark grey RAL7024. Corrosion resistance C5, ultraviolet resistance RUV5 according to EN 10169.

- Interior in Z275 galvanized steel.

- Insulation with glass wool, thickness 25 mm, density 24 kg/m3 :

- Thermal conductivity 0.035 W/(mk) (20/80°C).

- Fire classification A1 according to standard EN 13 501.1.

- Removable hatches facilitating access to the unit in confined spaces.

- ID suction and/or blowing register panel (accessory).

Equipment of the main modules

Motor fans

- Metallic freewheel type reaction fans (incombustible A1) associated with an ECM electronically commutated motor.

Engines with integrated electronic protection:

- UTBS-2: 0.46kW single-phase 230V, 50-60Hz, IP44, class B.

- UTBS-3: 2x0.45kW single-phase 230V, 50-60Hz, IP44, class B.

- UTBS-5: 2x0.85kW single-phase 230V, 50-60Hz, IP54, class F.

- UTBS-8: 2x1.00kW three-phase 400V, 50-60Hz, IP54, class F.

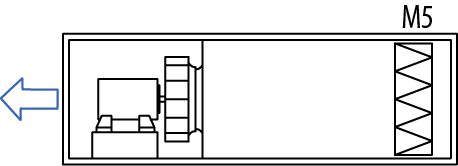

- Filters supplied as standard:

- FIFI M5 ePM10 50 pleated filters%.

- Location for a second filtration stage, optional filters.

- Holding system consisting of two clamping handles.

- Disassembly of filters from the side or below.

- Optional filters:

- FIFI F7 ePM1 55 mini-pleat filters% and FIFI F9 ePM1 80 minifold filters% to achieve a double filtration stage M5+F7 or M5+F9 or F7+F9.

Batteries

- 2 or 4 row hot water batteries (galvanized steel frame, copper tubes and aluminum fins).

- 4 or 6 row cold or reversible water batteries (galvanized steel frame, copper tubes, aluminum fins, 304 stainless steel condensate tray and droplet separator).

- Electric batteries (galvanized steel frame and shielded resistors) with manual (120°C) and automatic (75°C) reset protections, anti-radiation screen.

- Reversible direct expansion battery 1 or 2 circuits on 3 to 6 rows for operation as a condenser or evaporator. Copper tubes and collectors, aluminum fins, galvanized steel frame. Stainless steel condensate recovery tray and droplet separator. Provide a CTA kit with the direct expansion unit (not supplied) equipped with its own probes and temperature regulation system. In the case of a direct expansion battery, the CORRIGO regulator only manages the ventilation and does not manage the temperature regulation. Regulation in COP mode not compatible with a direct expansion battery.

UTBS ECOWATT PRO REG regulation

- CORRIGO regulation mounted/wired, integrated into the unit with remote touch control, allowing 3 operating modes:

|

FLOW RATE SETTINGS |

RECOMMENDED APPLICATIONS |

|

VAV MODE - VARIABLE FLOW: Variation of fan speed |

|

|

- Flow rate depending on a 0-10 V signal from the extraction, the remote control, an external probe (CO2, temperature, humidity, etc.) or a remote control (M/A + variation). |

- Compensation, controlled by a kitchen extraction, |

|

CAV MODE - CONSTANT FLOW: Fan speed set according to a precise flow |

|

|

- Manual entry (m3/h) of 3 flow rate settings type 0-PV-GV-BOOST. Manual operation or on time slot. |

- Installations requiring control of one or more specific flow rates. |

|

COP MODE - CONSTANT PRESSURE: Automatic variation of fan speed to maintain constant pressure |

|

|

- Constant pressure value measured by an external probe (option) located in the blowing duct network. |

- Multi-zone installations, associated with modulation of terminal flow rates. |

- UTBS ECOWATT PRO-REG delivered in CAV mode, without accessories.

Left servitude as standard (view in the direction of the air):

Interior version without roof:

|

UTBS 2 |

UTBS 3 |

UTBS 5 |

UTBS 8 |

|

|

A (mm) |

360 |

410 |

410 |

500 |

|

B (mm) |

750 |

1100 |

1500 |

1900 |

* With the support frame, the height increases by 80 mm.

Exterior version with roof:

| Size | HAS | B | C | D |

| UTBS-2 | 910 | 460 | 750 | 428 |

| UTBS-3 | 1260 | 522 | 1100 | 478 |

| UTBS-5 | 1660 | 536 | 1500 | 478 |

| UTBS-8 | 2060 | 640 | 1900 | 568 |

* With the support frame, the height increases by 80 mm.

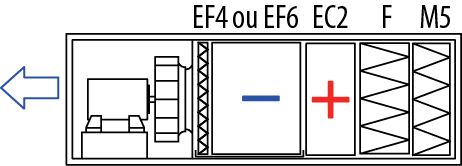

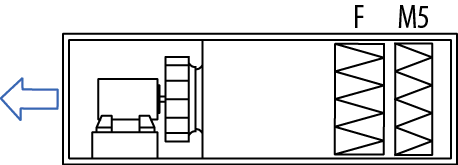

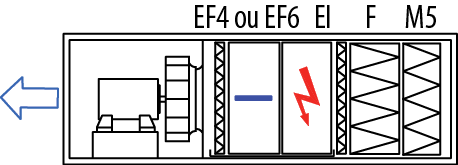

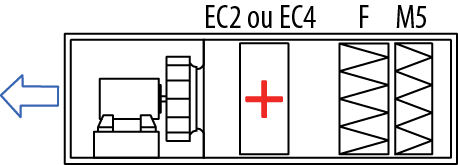

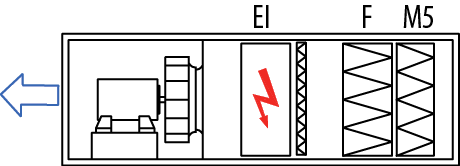

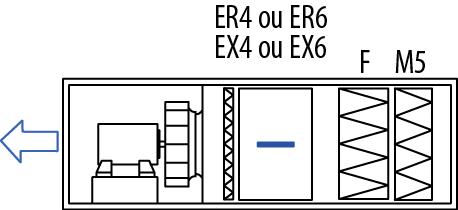

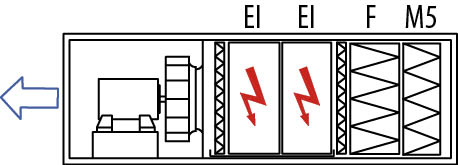

Main Box Configurations

Configuration 1: length 750 mm(*) |

Configuration 5: length 1455 mm |

Configuration 2: length 969 mm(*) |

Configuration 6: length 1455 mm |

Configuration 3: length 1455 mm |

Configuration 7: length 1205 mm |

Configuration 4: length 1455 mm |

Configuration 8: length 1455 mm |

| EC2: 2-row hot battery EC4: 4-row hot battery EF4/ER4: 4-row cold (or reversible) battery EF6/ER6: 6-row cold (or reversible) battery EX4: 4-row direct expansion battery EX6: 6-row direct expansion battery EI: Electric Battery M5: FIFI M5 ePM10 55 filter% F: FIFI F7 or FIFI F9 filter location (*) : unregulated version |

|

Detailed specifications

Detailed specifications

Text catalog pages (CT)

Catalog Pages - Other

Public tariff price

Public tariff price

Price catalog pages (CP)

Installation instructions

Installation instructions

Installation instructions (NT)

Installation instructions (NT) Other

Installation instructions (NT) Other languages

Fire / Smoke extraction certificates

Fire / Smoke extraction certificates

Fire classification report (PVFEU)

Performance / Environment Certificates

Performance / Environment Certificates

Declaration of performance (DOP)

Product environmental profile (PEP)

Electrical / ATEX Certificates

Electrical / ATEX Certificates

Electrical CE Declarations (DCCE)

Prescription assistance

Prescription assistance

Specification text (TP)

Commercial documents

Commercial documents

Commercial leaflet (FCOM)

For any questions, please send an email to optair@vim.fr

NINKASI - LYON

NINKASI - LYON

Restaurant chains

69 - Rhône

Installed products: